Entrar em contacto

Stella

Notícias

In this article, RTG container gantry crane is introduced in detail, including its definition, structure and parts, components function, application, specs, price etc. This article will make you learn more info about RTG crane for your handling needs.

A rubber tyre gantry (RTG) Crane is a mobile heavy-duty machine for container handling in ports, intermodal yards, and logistics hubs. It features a steel gantry structure mounted on rubber tires, enabling flexible movement across yards without fixed rails. With lifting capacities ranging from 30 to 65 tons under the spreader, RTGs can stack containers up to 1-over-6 high (7 tiers) and span up to 8 container rows plus a truck lane.

Equipped with 90° rotating tyres and cross-driving modes, RTGs move and work efficiently in tight spaces. Key components include a trolley with anti-sway technology, advanced PLC systems, and modular power options. It features remote monitoring, predictive maintenance, and automated container tracking to enhance productivity and safety.

Compared to rail-mounted gantry (RMG) cranes, RTGs provide unmatched mobility for dynamic yard layouts. Their robust design, eco-friendly variants, and adaptability make RTGs a cornerstone of modern container logistics.

Container Yards

Port Terminals

Freight Ports

Freight Sites

Temporary Logistics Hubs

Industrial Parks

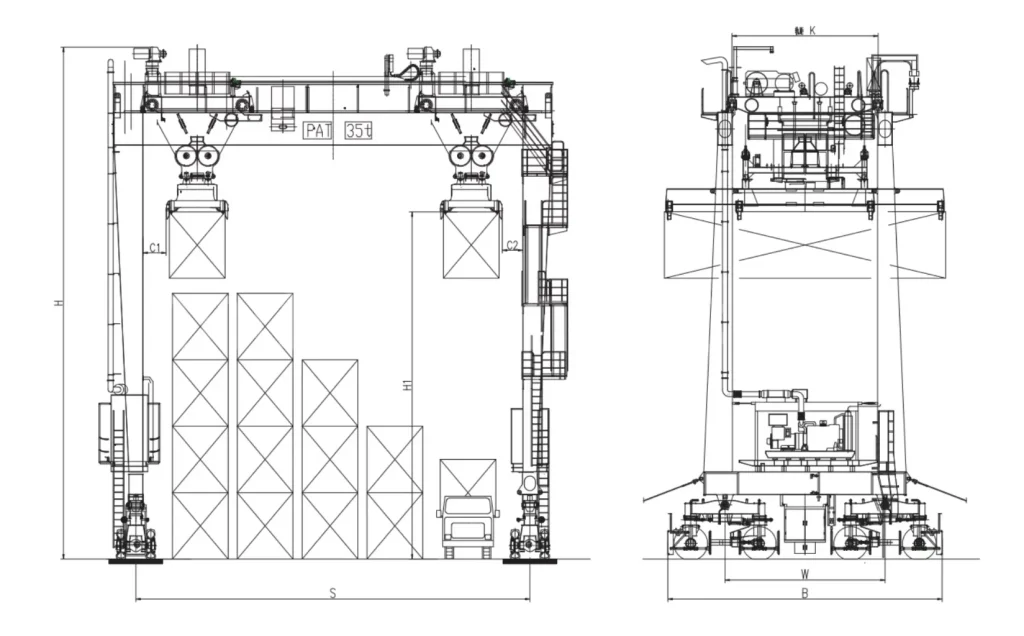

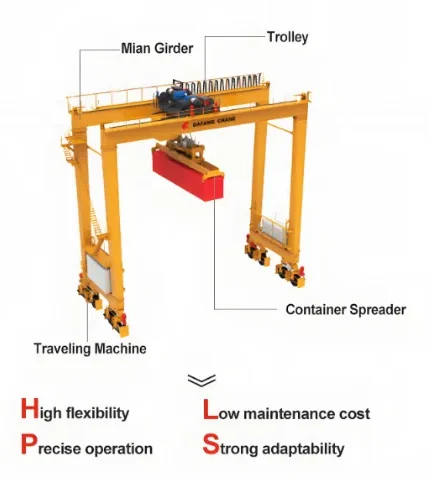

The RTG gantry crane is a highly efficient container handling equipment widely used in ports and storage yards. Its main structure includes a main girder, outriggers, a tire-operated system, and a lifting trolley.

Structural Drawings

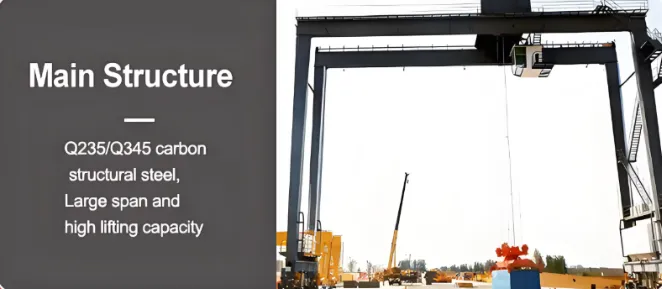

Main Structure

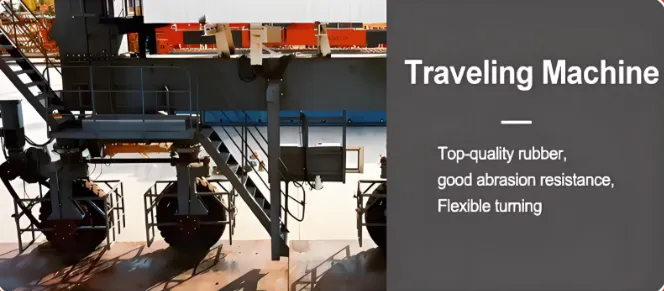

Traveling Machine

Crane Trolley

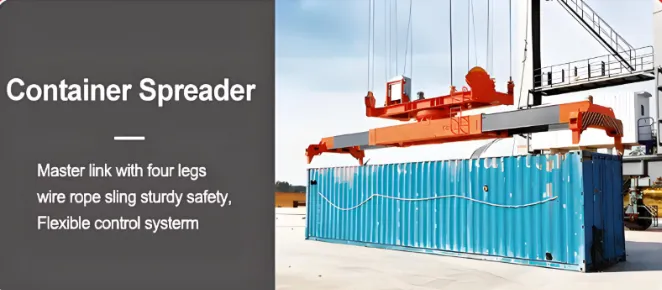

Container Spreader

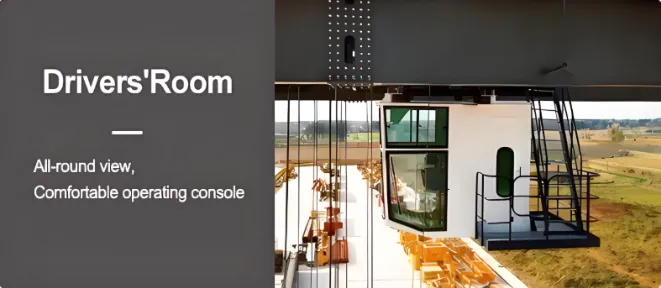

Drivers' Room

3D Structure and Parts

RTG crane is mainly used to remove, load and unload international standard containers. Widely used in container yards, they handle light-to-medium loads for efficient stacking.

Temporary Logistics Hubs

Container Yards

Inland Container Transfer Stations

Industrial Parks

Flexible Trackless Movement: Independently driven tires adapt to various site layouts, providing high maneuverability and rapid response to varying operational needs.

Energy-Efficient Design: Optimized energy management systems improve operational efficiency, reduce operating costs, and minimize environmental impact.

Intelligent Security System: Integrated PLC and remote monitoring, real-time diagnostics and maintenance ensure safe and reliable operation and minimize downtime.

Dafang Crane, as a professional container crane manufacturer and supplier, offers diverse gantry cranes, such as RTG container gantry crane, RMG container gantry crane, STS quay crane and so on.

If you want to choose the most suitable types of container gantry cranes to enhance efficiency and productivity. The following content will bring you a deeper understanding of RTG and RMG container cranes.

Rubber Tyre Gantry (RTG) Cranes are tyre-mounted gantry cranes, for flexible movement in yards.

They are special equipment to remove, load and unload international standard containers. Widely used in container yards, they handle light-medium loads for efficient stacking, reducing infrastructure costs.

Rail mounted container gantry (RMG) crane is a kind of rail mounted crane used to unload, stack and load 20ft, 40ft, 45ft lSO standard containers.

They run on fixed rails, designed for container handling. With high load capacity and stable operation, they excel in dense stacking at ports or large container yards, boosting storage efficiency.

| Mode | Pórtico para contentores RTG |

|---|---|

| Deadweight | 7592 KG |

| Capacidade de elevação | 35-70 ton |

| Span | 23.47/26 m |

| Altura de elevação | 15.5/18.5 m |

| Traveling Speed | 0-20 m/min |

| Wheel number | 16 |

| Maximum wheel load | 300 KN |

| Fonte de alimentação | 3 Phase AC 380V 50HZ |

| Control mode | Ground Control + Cabin Control (customized) |

| Work Duty | A4-A7 |

| Mode | Pórtico para contentores RMG |

|---|---|

| Deadweight | 10000 KG |

| Capacidade de elevação | 10-100 ton |

| Span | 30/35/40 m |

| Altura de elevação | 12.5/15.3/18.3 m |

| Cargo loading and unloading | 20ft 40ft container |

| Steel track recommendation | P43 |

| Fonte de alimentação | 3 Phase AC 380V 50HZ |

| Control mode | Ground Control + Cabin Control (customized) |

| Work Duty | A4-A7 |

Notice: The items listed only for reference. Customizable solutions are available.

| Types | Capacidade de elevação | Span | Altura de elevação | Specifications | Price(USD) |

|---|---|---|---|---|---|

| Pórtico para contentores RTG | 35-70 ton | 23.47/26 m | 15.5/18.5 m | 20', 40', 45' | $230000 ~ $350000, depending on specifications |

| Pórtico para contentores RMG | 10-100 ton | 30/35/40 m | 12.5/15.3/18.3 m | 20', 40', 45'; 双20 ', 20', 40 ', 45' | $150000 ~ $500000, depending on specifications |

Now, you must have a more comprehensive understanding of RTG container gantry cranes and RMG gantry cranes. And you must know how to choose right container gantry cranes to improve the work efficiency.

If you want to know more about gantry cranes, port cranes, overhead cranes, jib cranes, or crane parts, please contact our technicians and business managers. We will offer you the most professional guidance and support.