Prendre contact

Stella

Actualités

In this article, we will introduce RMG cranes in detail, invoving the definition, structure and parts, components function, features, application, specs, price etc. This article will help to know more comprehensively about RMG cranes for your handling needs.

The rail-mounted gantry (RMG) crane is a heavy-duty lifting device for container and heavy cargo handling. Unlike rubber-tired RTGs, they operate along fixed rails to ensure high positioning accuracy and stable movement. Their core structure includes a rigid gantry frame, a hoisting mechanism (for lifting/lowering cargo), a trolley (for horizontal adjustment), and a container spreader (to grip containers). Most RMG cranes use electric power, making them eco-friendly with low noise and emissions.

Key advantages are high stacking efficiency (handles multi-tier containers) and suitability for dense storage areas. They are widely used in ports, railway container yards, inland transfer stations, and industrial yards—ideal for scenarios needing consistent, heavy-load operations. Safety features like anti-sway systems and overload alarms further ensure reliable work.

Compared to the rubber tyre gantry (RTG) Crane, RMG cranes run on fixed rails to boast higher positioning accuracy and heavier load capacity for dense storage. They have limited mobility but excel in stable long-term fixed-site work, unlike RTGs’ flexible yard movement.

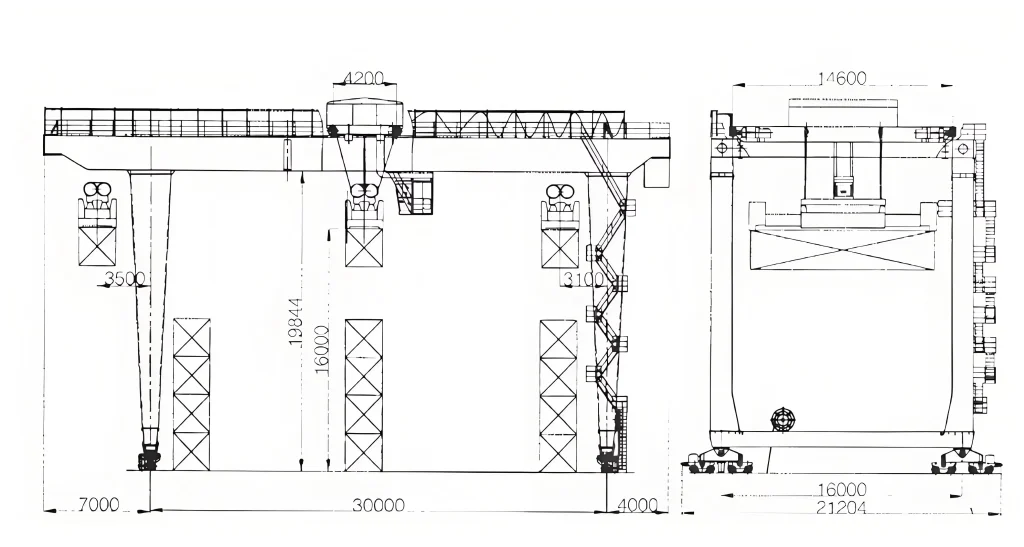

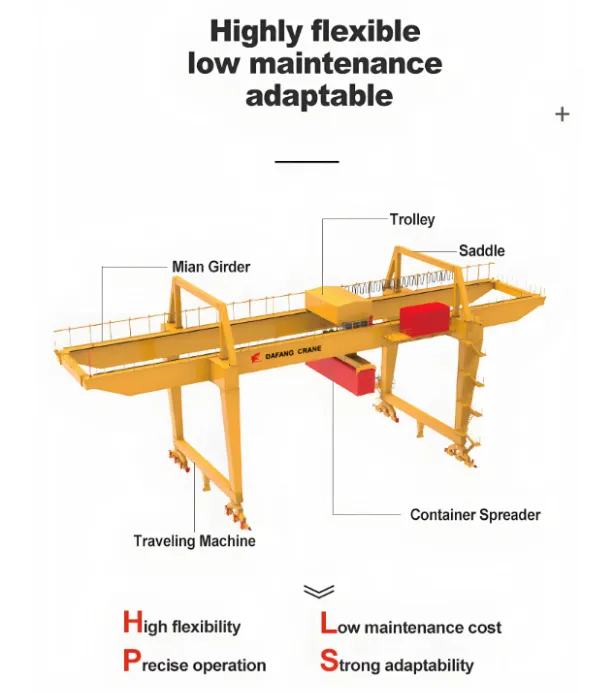

The RMG gantry crane is a highly efficient container handling equipment widely used in ports and storage yards. Its main structure includes a main girder, outriggers, a tire-operated system, and a lifting trolley.

RMG Crane Structural Drawings

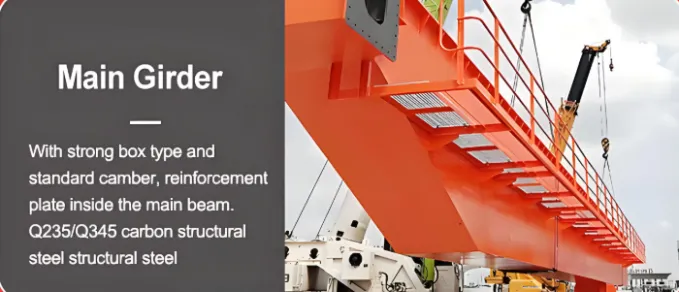

Main Girder

Traveling Machine

Crane Trolley

Container Spreader

Drivers' Room

RMG Crane 3D Structure and Parts

RMG crane is mainly used to remove, load or unload containers, heavy equipment assembly, industrial raw materials and refrigerated containers. Widely used in container terminals, transfer stations, logistics zones, assembly workshops, spacialized yards etc.

1. Port Container Terminals (for storing and transferring containers)

2. Railway Container Yards (for transferring containers to/from railway freight cars)

3. Inland Container Transfer Stations (for regional container transfer)

4. Specialized Container Yards (for centralized container storage)

5. Heavy Industrial Raw Material Yards (for hoisting steel, ore, etc.)

6. Port Bonded Logistics Zones (for container handling under supervision)

7. Heavy Equipment Assembly Workshops (for hoisting large industrial components)

8. Specialized Yards for Refrigerated Containers (for orderly storage of refrigerated containers)

1. Efficient Operation: The dual-sling design significantly improves loading and unloading efficiency, enabling rapid positioning and continuous operation, making it particularly suitable for high-throughput container yards.

2. Stable Operation and Energy-Saving: The flat, fixed track ensures smooth movement, minimizing vibration and impact. This effectively reduces energy consumption and meets environmental protection requirements.

3. Highly Automated and Intelligent: Applying laser scanning, GPS positioning and sensor technology, it identifies container locations, plans routes, and completes loading and unloading tasks. It reduces manual intervention and improves operational accuracy and safety.

Dafang Crane, as a TOP10 container crane manufacturer and supplier in China, offers various container gantry cranes, such as RMG container gantry crane, RTG container gantry crane, STS quayside crane and other port cranes.

If you want to choose the most suitable types of container gantry cranes to enhance efficiency and productivity. The following will make you gain a deeper understanding of RMG and RTG container cranes.

RMG cranes are rail mounted cranes to unload, stack and load 20ft, 40ft, 45ft lSO standard containers.

They run on fixed rails, for container handling. With high load capacity and stable operation, they excel in dense stacking at ports or large container yards, boosting storage efficiency.

RTG Cranes are tyre-mounted gantry cranes, for flexible movement in yards and terminals.

They are special equipment to remove, load and unload international standard containers. Widely used in container yards, they handle medium loads for efficient stacking, reducing infrastructure costs.

| Mode | Portique à conteneurs RMG |

|---|---|

| Deadweight | 10000 KG |

| Capacité de levage | 10-100 ton |

| La portée | 30/35/40 m |

| Hauteur de levage | 12.5/15.3/18.3 m |

| Cargo loading and unloading | 20ft 40ft container |

| Max Wheel Load | 250/280/300 KN |

| Alimentation électrique | 3 Phase AC 380V 50HZ |

| Control mode | Ground Control + Cabin Control (customized) |

| Obligation de travail | A4-A7 |

| Mode | RTG Container Gantry Crane |

|---|---|

| Deadweight | 7592 KG |

| Capacité de levage | 35-70 ton |

| La portée | 23.47/26 m |

| Hauteur de levage | 15.5/18.5 m |

| Traveling Speed | 0-20 m/min |

| Maximum wheel load | 300 KN |

| Alimentation électrique | 3 Phase AC 380V 50HZ |

| Control mode | Ground Control + Cabin Control (customized) |

| Obligation de travail | A4-A7 |

Notice: The items listed only for reference. Customizable solutions are available.

| Types | Capacité de levage | La portée | Hauteur de levage | Specifications | Price(USD) |

|---|---|---|---|---|---|

| Portique à conteneurs RMG | 10-100 ton | 30/35/40 m | 12.5/15.3/18.3 m | 20', 40', 45'; 双20 ', 20', 40 ', 45' | $150000 ~ $500000, depending on specifications |

| RTG Container Gantry Crane | 35-70 ton | 23.47/26 m | 15.5/18.5 m | 20', 40', 45' | $230000 ~ $350000, depending on specifications |

Now, you must have a deeper understanding of RMG container gantry cranes. And you must know how to choose right container gantry cranes to improve the work efficiency.

If you want to know more about gantry cranes, port cranes, overhead cranes, jib cranes, or crane parts, please contact our technicians and business managers. We will offer you the most professional guidance and support the most professional guidance and support.