Prendre contact

Stella

Actualités

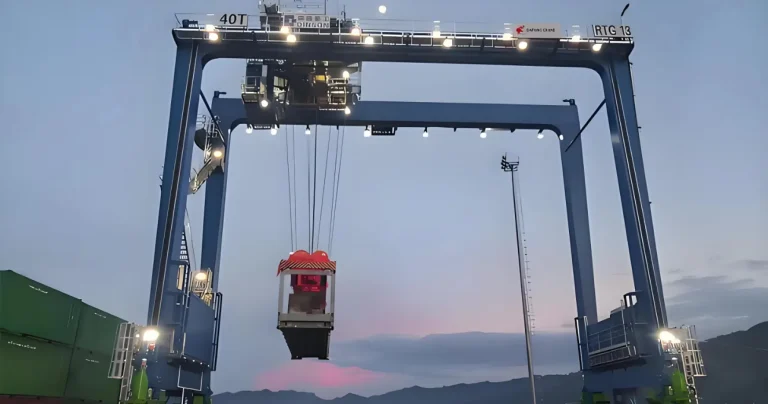

Global trade relies on the seamless movement of containers across ports and yards. Container cranes move millions of containers yearly across ports and yards — whether they are Rubber Tyre Container Crane(RTG Crane), Rail-mounted Container Crane(RMG Crane), Ship-to-shore quay (STS crane) or container straddle carrier. Therefore, container gantry cranes are the essential equipment to make international import and export trading possible.

These massive container lifting machines may appear complex, but their core components and operating principles follow a logically rigorous, streamlined, and efficient design, ensuring the efficiency of the global supply chain.

Henan Dafang Heavy Machine Co Ltd. has been manufacturing and exporting container cranes for over 20 years. To better use container gantry cranes and improve working efficiency, it is essential to break down their core components, see the differences among them and see how they work together to safely and quickly lift, move, and stack heavy containers.

Every container crane has several basic components that work together to drive its function.

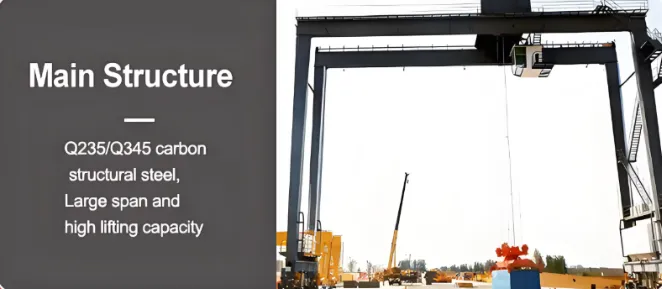

Main Structure

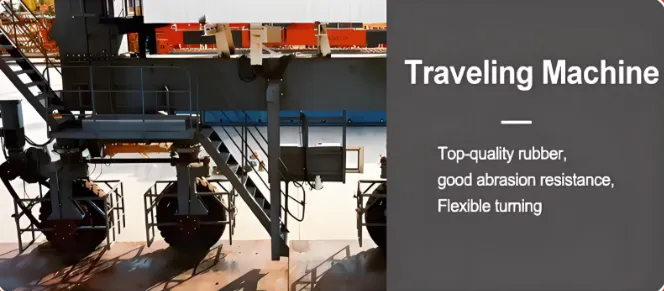

Traveling Machine

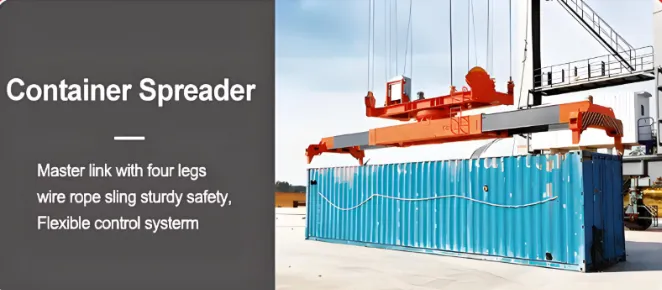

Container Spreader

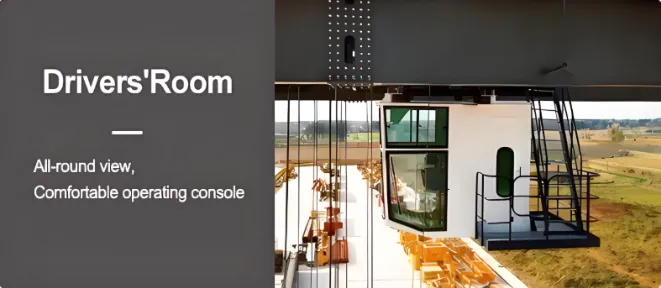

Drivers' Room

The crane’s operation follows a streamlined, four-stage process:

After reading this article, you now understand the components and working principle of container gantry cranes. Dafang Crane team hope this article will provide some insights for your selection of container gantry cranes. Please do not hesitate to contact us if you have any questions. We will provide professional support and guidance.