Prodotti

Electric Transfer Carts are highly efficient material handling equipment for factories, warehouses, ports, and other scenarios. Powered by electricity, they features strong load capacity, stable operation, zero emissions, and low noise. They enable automated or semi-automated point-to-point transportation of goods, suitable for various heavy objects such as steel, molds, and parts, reducing labor costs and improving logistics efficiency. They are core auxiliary equipment for modern industrial production.

Henan Dafang Crane, a reliable electric transfer carts manufacturer and supplier in China, has produced transfer carts for 20 years. Dafang Crane offers a wide range of electric transfer carts for sale. Each type comes with detailed specification (covering load capacity, lifting height, etc.) and customizable solutions for specific requirements.

As a direct electric transfer carts factory, we offer competitive Electric Transfer Cart Price, ensuring cheaper price without quality compromise. Choose Dafang’s electric transfer carts for a reliable, cost-effective transportation solution!

Get Free Quote

Core Features:

Application Scenarios:

Core Features:

Application Scenarios:

Core Features:

Application Scenarios:

Core Features:

Application Scenarios:

Core Features:

Application Scenarios:

Core Features:

Application Scenarios:

Core Features:

Application Scenarios:

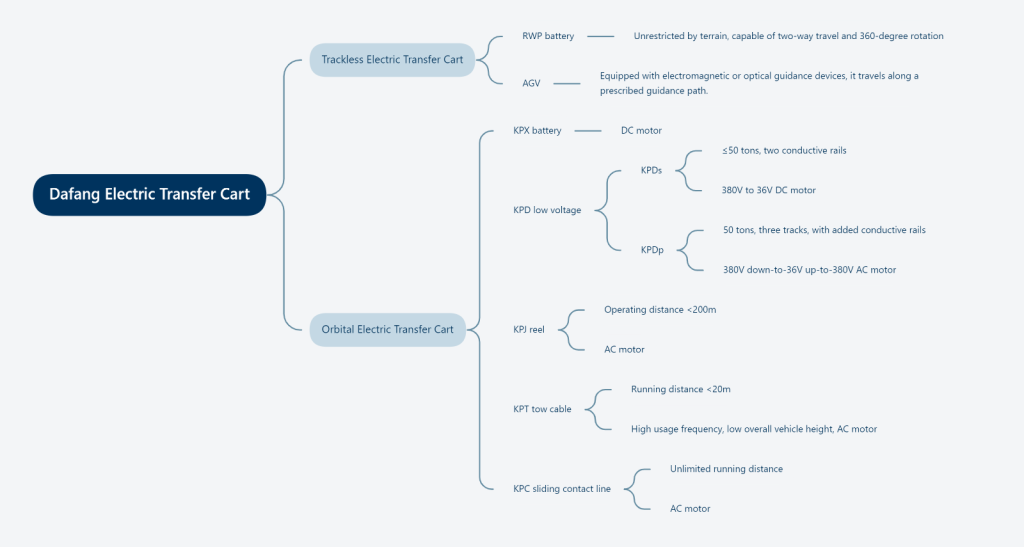

| Electric Flat Car Series Differences Table | |||||||

| Alimentazione | Low-Voltage Rail Power Supply | Battery Power Supply | Cable Reel Power Supply | Trailing Cable Power Supply | Conductor Rail Power Supply | Trackless Electric Flat Car | |

| Product Mode | KPDZ (Two-Phase) | KPDS (Three-Phase) | KPX | KPJ | KPT | KPC | BWP |

| Working Principle | 380V to 36V Two-Phase | 380V to 36V Three-Phase to AC 380V | Battery provides power to DC traction motor | AC 380V cable, operating system controlled by 36V power supply | Battery provides power to DC traction motor | ||

| Running Direction | Start, Stop, Forward, Reverse, Speed Adjustment | Start, Stop, Forward, Reverse | Start, Stop, Forward, Reverse, Left Turn, Right Turn, Speed Adjustment | ||||

| Load Capacity | ≦50t | >50t | Any load capacity | ||||

| Frequency of Use | High frequency of use, medium and long-distance transportation | Low frequency of use, long-distance transportation | High frequency of use, maximum operating distance can reach 200 meters. | Short distance (≤20m), high frequency of use, low overall vehicle height | Limited by installation location, installed in a trench in the middle or outside of the track, with cover plate and automatic flip plate | ||

| Operating Distance | Operating distance exceeding 70 meters requires increasing the number of transformers to compensate for track voltage drop | Operating distance exceeding 50 meters requires adding a cable guide to assist in winding | For short distances and slow operating speeds, a drag chain can be used to reduce cable wear | Short operating distance, extremely high frequency of use, low overall vehicle height, assembly line operation | |||

| Power Supply Method | Two conductive rails, track insulation treatment, two-phase power supply | Three conductive rails (additional conductive rail), track insulation treatment, three-phase power supply | Battery | Cable placed in the center of the two tracks | Battery | ||

| Motore | DC motor | AC motor | DC motor/Low-voltage AC motor | AC motor | AC motor | AC motor | DC motor/Low-voltage AC motor |

| Suitable Occasions | S-shaped tracks, curved tracks and high-temperature environments | S-shaped tracks, curved tracks and flammable and explosive environments, ferry applications. | Harsh environments, high-temperature environments, explosion-proof environments | Harsh environments, high-temperature environments, preferred for workshop assembly lines | Ground surface (concrete/steel plate) | ||

| Lifespan | Battery requires regular maintenance, lifespan approximately 2.5 years | Battery requires regular maintenance, lifespan approximately 2.5 years | |||||

| Industry | Steelmaking, steel casting and spare parts manufacturers, logistics | ||||||

Dafgang Crane specializes in offering customized material handling solutions to meet clients' needs. We can provide modular designs to suit diverse needs while ensuring structural soundness and standardized production.

If you have any specific requirements or need further assistance, please contact our expert team and discuss about your working conditions and demands. We will offer satisfactory custom solutions and professional support.

Get Free Quote

Henan Dafang Crane has specialized in offering electric transfer carts for 20 years. Dafang constantly provides high-quality and satisfactory crane spare parts to meet clients' needs. Besides of electric transfer carts, we also provide electric winch machines, lift platforms, and electric hoists to meet customers' practical needs.

Dafang supplies high quality overhead cranes, gantry cranes, jib cranes, electric hoists and crane spare parts etc. You can fill out the form below, and we will contact you as soon as possible

Stella