Entrar em contacto

Stella

Notícias

A gantry crane is a common and advanced heavy-duty lifting equipment. It has become more and more indispensable in various industrial and logistical settings, including ports, warehouses, construction sites, and manufacturing facilities. Its versatility, efficiency, and ability to precisely handle heavy loads together make gantry cranes' wide application.

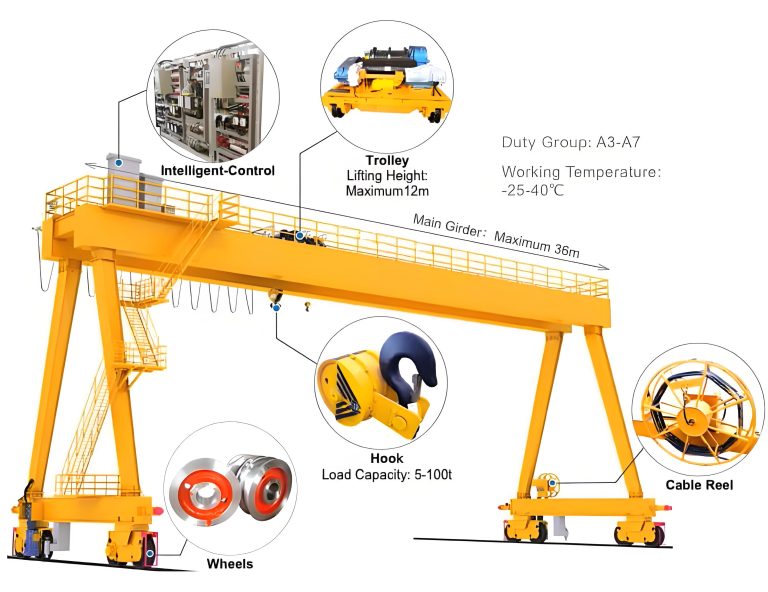

To understand how a gantry crane works, we first need to know its main components. It mainly consists of a main beam, supporting legs, a trolley running mechanism, a lifting mechanism, and a crane traveling mechanism.

First, let us look at gantry cranes' structure and components. Therefore, we can better understand the working principle of overhead cranes from the mechanical structure, electrical control system, and operational process.

The Main Beam: serves as the horizontal support structure responsible for carrying the load. This robust beam is typically constructed from high-strength steel to ensure durability and stability under heavy loads. Mounted on either end of the main beam are the supporting legs. It provides vertical support and stability, allowing the crane to operate on various terrains.

The Trolley Running Mechanism: enables the trolley to move horizontally along the main beam. This mechanism is crucial for positioning the load accurately over the desired location. The lifting mechanism is responsible for raising and lowering the load. It consists of a hoist, wire ropes, and a pulley system that work in tandem to provide smooth and controlled lifting operations.

The Crane Traveling Mechanism: allows the entire crane to move longitudinally along the tracks or ground surface. This feature provides additional flexibility and mobility, enabling the crane to access different areas of the work site.

Together, these components form a highly efficient and reliable lifting system that can handle a wide range of materials and loads, from containers and heavy machinery to construction materials and raw goods.

The working principle of a gantry crane is based on the coordinated operation of various mechanisms.

First, the gantry traveling mechanism drives the entire crane to move along the fixed track on the ground, so that the crane can reach the position where the goods need to be lifted. Then, the trolley running mechanism makes the trolley (equipped with the lifting mechanism) move horizontally along the main beam. This horizontal movement adjusts the position of the lifting hook above the goods to be lifted accurately.

When the lifting hook aligns with goods, the lifting mechanism starts to work. The lifting mechanism consists of a motor, a reducer, a drum, a steel wire rope and a hook. The motor drives the reducer to rotate, and the reducer drives the drum to rotate. As the drum rotates, the steel wire rope wound on it is released or wound up. After releasing the steel wire rope, the hook descends to hook the goods. After firmly hooking the goods, the motor reverses, driving the drum to wind up the steel wire rope, and the hook rises with the goods.

After lifting goods to the required height, the gantry traveling mechanism and the trolley running mechanism work together again. The gantry traveling mechanism moves the entire crane to the target location, and the trolley running mechanism adjusts the horizontal position of the goods again.

Finally, the lifting mechanism releases the steel wire rope, and the hook descends to place the goods at the designated position, thus completing a lifting operation.

To ensure the safe and efficient operation of the gantry crane, users must pay attention to regular maintenance and inspection.

In conclusion, a gantry crane realizes the lifting and transportation of goods through the coordinated work of various mechanisms. In addition, regular maintenance and inspection can prolong its service life and ensure operational safety.