Ponte en contacto

Stella

Noticias

Dafang Crane, a professional goliath crane manufacturer and supplier in China, designs this gantry crane to handle massive loads in industrial settings. Customers often use it in shipbuilding, construction, and manufacturing industries, particularly in outdoor environments such as shipyards, logistics transfer centers, and fabrication sites.

Here is a comprehensive introduction to its definition, types, technical specs, applications, and features.

A Goliath Crane, also known as a gantry crane, is a large, heavy-duty lifting machine. It features a horizontal beam supported by two vertical legs that run on ground rails. This special design enables it to move heavy loads both horizontally and vertically along the tracks.

MH Single Girder Gantry Crane

U Double Girder Gantry Crane

BMH Single Girder Gantry Crane

The goliath crane is a highly efficient crane equipment. Its main structure includes main girders, supporting legs, a lifting trolley, and safety devices. Main Components:

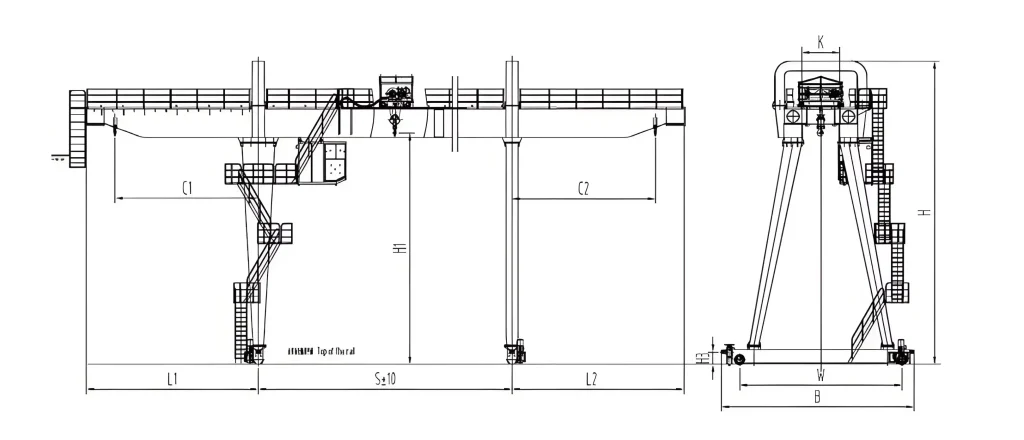

Goliath Crane Structural Design Drawings

| Aspects | Parameters |

|---|---|

| Capacidad de elevación | Single girder: 1–50 tons Double girder: 5–800 tons (specialized models) |

| Span | 4–135 meters (depending on the type and application) |

| Altura de elevación | Typically 6–30 meters, but customizable for specific needs |

| Clase trabajadora | A3 (light duty) - A8 (heavy duty), based on usage frequency and load cycles |

| Fuente de alimentación | 3 Phase AC 380V 50HZ |

Customers always apply different types of Goliath gantry cranes to realize light-to-medium as well as heavy-duty operations in the following industries and scenarios.

3 Key Advantages

Heavy Load Handling and High Precision: Lifting massive objects that other common cranes cannot manage. Offering ±4 mm load positioning accuracy.

Versatility: Adaptable to various industries and tasks, including remote operation (two cranes controlled by one operator for enhanced safety).

Space Efficiency: Ground-level rails allow unobstructed overhead space compared to overhead cranes.

3 Key Limitations

High Initial Cost: Expensive to purchase, install, and maintain due to their size and complexity.

Infrastructure Requirements: Requires dedicated ground rails and strong foundations.

Mobility Constraints: Fixed to rail tracks, limiting movement to specific areas.

Dafang Crane, Top 10 Goliath crane manufacturer and supplier in China, offers diverse goliath cranes, mainly single girder goliath cranes, double girder goliath cranes, semi goliath cranes. The following content will help users better learn about goliath gantry cranes and choose the most suitable type.

Capacity: 1–50 tons; Span: 4–35 meters

Lightweight, Compact design, cost-effective, Stable and reliable. Suitable for general material handling (e.g., factories, warehouses).

Capacity: 5–800 tons; Span: 12–130 meters

Excellent stability, Large space operation, Efficient and Energy-saving. Heavy-duty design for lifting extremely large loads (e.g., ship hulls, industrial machinery).

Capacity: 2–20 tons; Span: 4-28 meters

High flexibility and adjustable span and height according to actual needs. Suitable for various complex working conditions, ideal for confined spaces.

Notice: The items above are only for reference. Customizable solutions are available.

Now, you must have a comprehensive understanding of goliath cranes. And you must know how to choose the right types to improve the work efficiency and how to do the maintenance work in daily use.

If you want to know more about gantry cranes, port cranes, overhead cranes, jib cranes, or crane parts, please contact our team. We will offer you the most professional guidance and support.