Ponte en contacto

Stella

Noticias

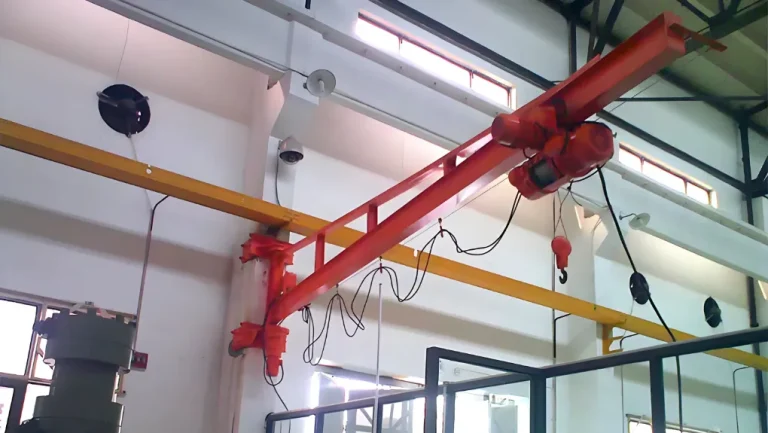

Installing a cantilever crane can enhance production efficiency and improve workplace safety. This equipment is specifically for handling heavy-duty lifting operations, enabling time-saving and efficient material handling within the workspace. Furthermore, it can operate in tandem with existing overhead crane systems to significantly boost operational efficiency.

In this article, we will introduce jib cranes in detail, including the definition, structure and parts, features, and application. We will help you learn more information about jib cranes. And we hope you can make better use of them for your handling needs in factories or workshops.

A jib crane is a compact lifting device featuring a horizontal rotating arm for load positioning, widely used in industrial material handling. It has five common types: Floor Mounted, Wall Mounted, Wall Traveling, Column Articulating, and Slewing Mobile.

With load capacities ranging from 0.25t to 20t, cantilever jib cranes offer flexible rotation (180°- 360°) and can adapt to both fixed and mobile lifting needs in confined or open spaces.

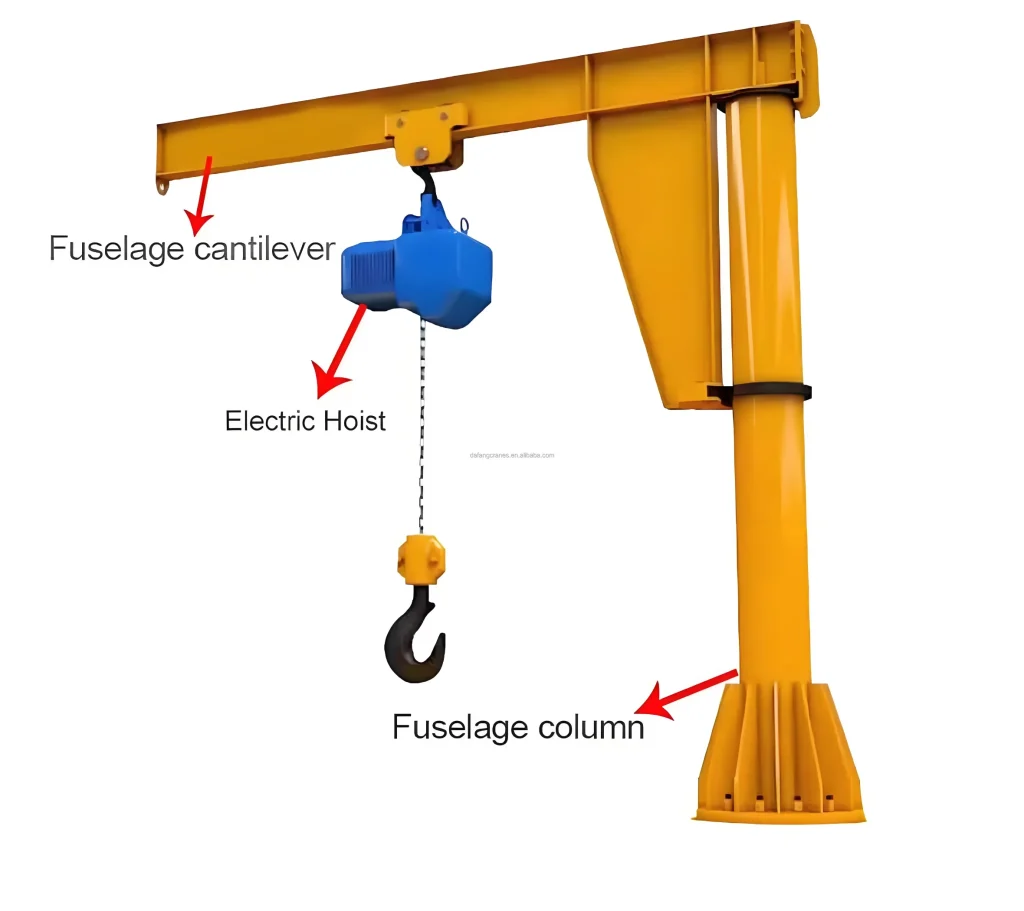

Structural Drawings

Dafang Crane, as a professional jib crane manufacturer and supplier, offers diverse cantilever cranes, such as Floor Mounted, Wall Mounted, Wall Traveling, Column Articulating, and Slewing Mobile jib cranes.

Features: Floor-mounted jib cranes can support large load lifting, stable and non-occupying wall/column space

Application: Heavy-duty fixed-point operations in factories, such as heavy equipment assembly areas, warehouse fixed unloading stations, and machining workshop workpiece hoisting.

Features: Wall-mounted design saves ground space, suitable for medium and light load lifting. With a rotatable cantilever, cover a large working range.

Application: Compact space operations like small workshops, maintenance rooms, and retail warehouse goods handling.

Features: The jib arm can rotate 180° or 360°. The angle can adapt to users' actual requirements. And users can customize the length of jib arm to suit workspaces and lifting requirements.

Application: Long-span continuous operations in production lines, such as automobile assembly lines, electronic component assembly workshops, and long-distance material transportation in warehouses.

Features: The slewing jib can rotate and extend in many directions so it can efectively make use of vertical and horizontal space.

Application: Narrow-space multi-angle operations, such as machine tool side workpiece loading or unloading, small parts assembly areas, and equipment maintenance in confined spaces.

Features: With mobility, no fixed installation required. The jib can achieve a full 360° swing around the column or a partial 180-270° swing.

Application: Outdoor temporary or mobile operations, such as construction site material transfer, logistics yard temporary loading or unloading, and outdoor equipment maintenance.

Users often use jib cranes in small-scale workspaces, because they can handle flexibly lift light-to-medium loads in workshops, warehouses, production lines and so on. Here is the detailed introduction.

Notice: The items listed only for reference. Customizable solutions are available.

Now, you must have a more comprehensive understanding of slewing jib cranes. And you must know how to choose right slewing cantilever jib cranes to improve work efficiency in warehouses and plants.

If you want to know more about overhead cranes, gantry cranes, port cranes, quay cranes, or special crane parts, please contact our technicians and business managers. We will offer you the most professional guidance and support.