I. Product Structure and Visual Characteristics

Wheel Body: Primarily yellow (a common warning/identification color for industrial equipment), manufactured via forging/precision casting techniques. Spoke distribution incorporates weight-reduction/mounting holes, balancing strength with lightweight construction.

Wear-Resistant Lining: Black composite wear layer within the flange groove (typically MC nylon, polyurethane or other polymer materials) significantly reduces wire rope abrasion.

Bearing System: Integrated high-precision rolling bearings ensure smooth pulley rotation and minimise friction losses. Shaft ends are fabricated from heat-treated alloy steel for enhanced impact resistance and wear endurance.

II. Core Advantages

- Long Wire Rope Lifespan: The self-lubricating, low-friction properties of the wear-resistant lining reduce wire rope wear rates by over 30%, indirectly lowering operational maintenance costs.

- Lightweight and High Strength: When incorporating alloy or composite reinforcement, weight is reduced by 20%–40% compared to all-steel pulleys, yet it can withstand loads ranging from tens to hundreds of tonnes, meeting the lightweight requirements of mobile cranes (e.g., truck-mounted and crawler cranes).

- Low Noise and High Efficiency: The combination of wear-resistant layers and bearings reduces pulley operating noise by 15dB while enhancing transmission efficiency, thereby reducing energy consumption.

III. Typical Application Scenarios

The Crane pulley wheel is widely employed in bridge overhead cranes, gantry cranes, electric hoists, port lifting equipment:

- Workshop bridge overhead cranes: Functioning as pulley block components within hoisting mechanisms, they can facilitate smooth lifting and lowering of loads together with wire ropes.

- Port container cranes: During high-frequency, heavy-load operations, wear-resistant linings extend wire rope lifespan and enhance operational stability.

Case Studies Show

Crane pulleys, as core lifting components, play a pivotal role across multiple industries. Their application case studies are as follows:

1. Construction Industry

- Construction Efficiency Enhancement: A construction company replaced traditional pulleys with bearing-equipped crane pulleys on cranes. The low-friction properties of the bearings minimized equipment jamming, enabling smoother hoisting of heavy construction materials such as steel beams and concrete blocks. This reduced equipment downtime by 50%.

- Heavy Component Installation: During large-scale bridge construction, pulley blocks formed by Crane Pulleys efficiently lifted and precisely positioned hundred-tonne steel box girders, ensuring installation accuracy under complex conditions.

2. Port and Logistics Sector

- Wire Rope Lifespan Extension: Qingdao Port employs Crane Pulleys with modified nylon liners in the pulley blocks of its gantry cranes. The self-lubricating properties of nylon liners substantially reduce wire rope wear, decreasing replacement frequency by 40%. This not only saves operational costs but also ensures continuity in handling cargo such as containers and large machinery components.

- Cargo Transfer: Adopting the Crane Pulley system, ports can rapidly execute vertical and horizontal transfers of heavy cargo (such as marine engines and mining machinery) from vessels to quays, enhancing logistics throughput efficiency.

3. Mining Industry

- Maintenance Cost Optimization: A major Shanxi coal mine replaced traditional sheave liners in mine hoist sheaves with Crane Pulley liners made from MC nylon. The high wear resistance of the nylon liners extended equipment maintenance intervals from 3 to 8 months, yielding annual maintenance cost savings exceeding ¥200,000 while enhancing the safety and operational efficiency of the ore hoisting system.

4. Manufacturing Industry

- Conveyor System Upgrade: A manufacturing enterprise upgraded bearing-equipped Crane Pulleys within its workshop material conveyor lines. The bearings' ‘friction reduction + damage resistance’ properties increased conveying efficiency by 15% while reducing spare part replacement frequency.

- Heavy Equipment Assembly: In heavy machine tool assembly workshops, Crane Pulleys assisted in handling multi-tonne machine tool bed and spindle components, simplifying the difficulty of heavy object relocation in production processes and boosting assembly efficiency.

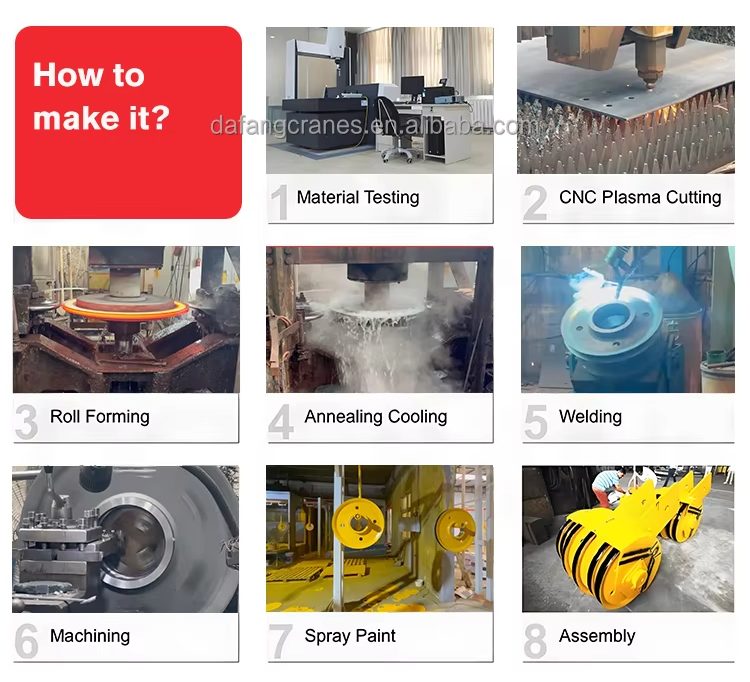

IV. Eight Producing Procedures of Crane Wheels

- 1. Material Testing

- 2. CNC Plasma Cutting

- 3. Roll Forming

- 4. Annealing Cooling

- 5. Welding

- 6. Machining

- 7. Spray Painting

- 8. Assembly

V. Crane Pulley Wheels Maintenance Guidelines

This pulley design balances strength, durability and operational efficiency through its ‘wear-resistant lining + precision bearings + lightweight structure’ configuration, serving as a critical component for load transfer and wire rope guidance in lifting equipment.

1. Regularly inspect wear-resistant lining thickness: Replacement is recommended when lining thickness wears to one-third of its original dimension.

2. Monitor bearing condition: Verify lubrication and rotational smoothness to prevent binding. And address abnormal noises or restricted movement promptly.

3. Inspect pulley structure: Check for cracks or deformation to ensure load-bearing safety.