تواصل معنا

ستيلا

أخبار

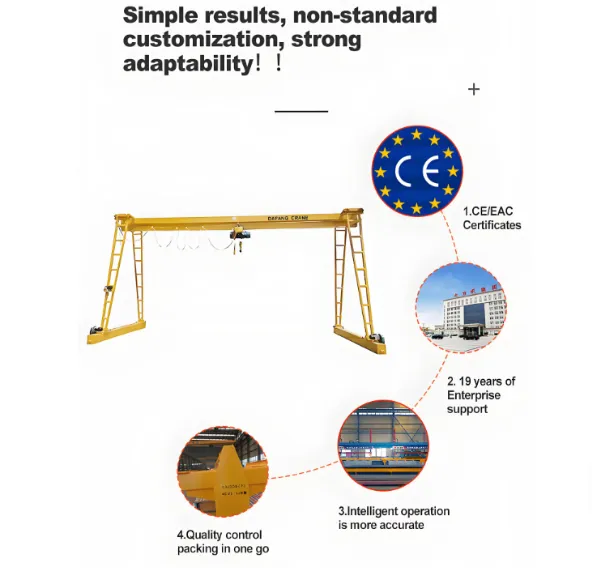

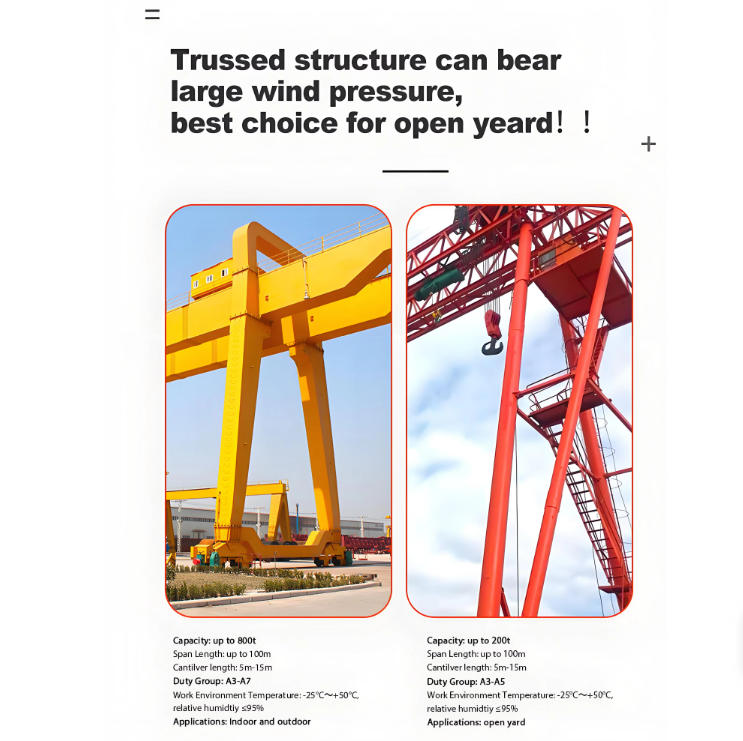

Truss Crane, also known as truss-type gantry crane, is a lifting equipment with a truss-structured main beam. Available in single-girder MH Truss type (≤20 tons) and double-girder MG Truss type (60-300 tons), a gantry truss crane can adapt to diverse outdoor tasks with strong wind resistance.

Here, truss crane is introduced in detail, including its definition, structure, working principle, application, specs etc. This article will make you learn more info about truss crane for your needs.

Truss Crane refers to a gantry crane whose main beam adopts a truss design. This design is an assembly of steel rods connected via bolts or welding to form triangular truss units. Composed of steel members connected into triangular units, it features light weight, large span, and strong wind resistance.

This triangular structure effectively disperses stress, enabling the main beam to bear loads while significantly reducing self-weight (30%-50% lighter than solid beams). Compared with conventional cranes, it excels in large-span applications (7.5-35 meters customizable) as it requires fewer support columns, lowering infrastructure costs.

Unlike solid-beam cranes, its hollow truss design minimizes wind resistance and balances load-bearing capacity and material efficiency. It is suitable for light-to-medium load operations in open-air or large-space environments such as freight yards, ports, and heavy-duty workshops. It is widely used for goods transfer, component hoisting, and other scenarios requiring long-span coverage. It balances efficiency, cost, and environmental adaptability.

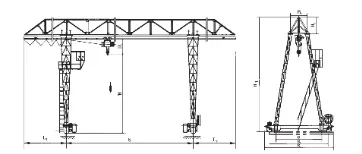

MH Truss Type Single Girder Gantry Crane Structure

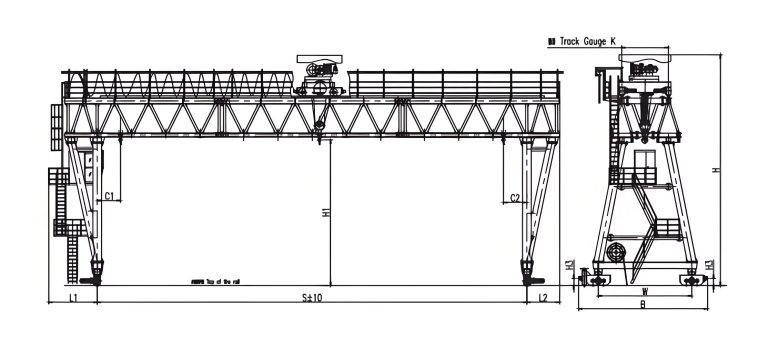

MG Truss Double Girder Gantry Crane Structure

MH Truss VS MH Box

MG Truss VS Mg Box

Dafang Crane, as a professional gantry truss crane manufacturer and supplier in China, offers MH single girder truss crane, MG double girder truss crane and semi truss crane etc.

MH Single Girder Truss Crane is a specialized gantry crane integrating single main beam and truss structure. Its main load-bearing beam adopts triangular truss units (composed of angle steel/channel steel), balancing light weight (30% lighter than solid-beam models) and stable load-bearing.

Typically with a span of 7.5-31.5m and load capacity of 3-20 tons, it excels in wind resistance (hollow truss reduces wind load by 40%)—ideal for open-air or large-space scenarios. It’s widely used in freight yards, logistics warehouses, and port branches for palletized goods transfer, semi-finished product hoisting, and light container handling, with low infrastructure and maintenance costs.

MG Double Girder Truss Crane is a heavy-duty gantry crane featuring dual truss-structured main beams. Its two load-bearing beams are made of steel members (angle steel, I-steel) connected into triangular truss units, balancing high load capacity and low self-weight.

With a typical load capacity of 5-200 tons and span of 18-35 meters, it outperforms single-girder models in heavy lifting. The hollow truss design reduces wind resistance by 50%, suiting open-air operations. Widely used in large freight yards, port trunk terminals, and heavy workshops for hoisting large components, containers, and bulk materials, it offers stable performance with lower infrastructure and maintenance costs.

Production Drawings

Steel Plate Unfolding

Main Girders Welding

End Beams Machining

Pre-assembly

Electric Hoists Producing

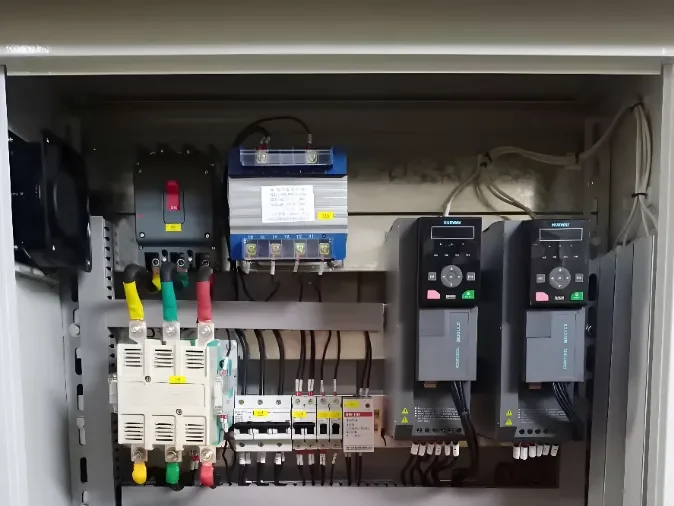

Electrical Control Units

Product Inspection

Packaging and Delivery

Descaling

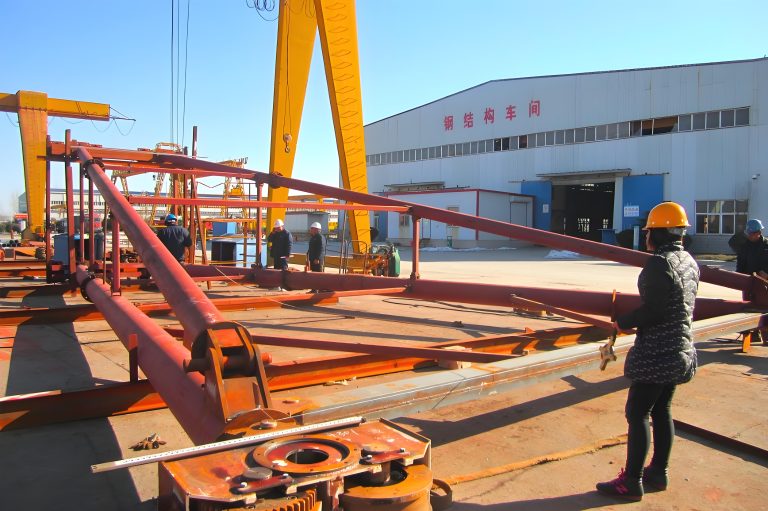

Pre-assembly of Support Legs

Main Beam Production

Welding

Main Beam Sectioning

Painting

Truss crane is mainly used for material handling and has a variety of functions to efficiently accomplish the loading, unloading, handling, and stacking of goods.

Bridge Construction Sites

Infrastructure Construction Sites:

| Main Mode | MH Truss |

|---|---|

| قدرة الرفع | 1-32 ton |

| فترة | 3-31.5 m |

| ارتفاع الرفع | 6-30 m |

| درجة حرارة العمل | -20℃~+40℃ |

| مزود الطاقة | 3 Phase AC 380V 50HZ |

| آلية الرفع | CD/MD Electric hoist |

| واجب العمل | أ3-أ5 |

| Main Mode | MG Truss |

|---|---|

| قدرة الرفع | 60-300 ton |

| فترة | 18-35 m |

| ارتفاع الرفع | 10-12 m |

| درجة حرارة العمل | -20℃~+40℃ |

| مزود الطاقة | 3 Phase AC 380V 50HZ |

| آلية الرفع | Electric Hoist Trolley |

| واجب العمل | م3 |

Notice: The items list only for reference. Customizable solutions are available.

| Types | قدرة الرفع | Price(USD) |

|---|---|---|

| MH Single Girder Truss Crane | 3-20 ton | $35000 ~ $105000, depending on specifications |

| MG Double Girder Truss Crane | 60-300 ton | $150000 ~ $1250000, depending on specifications |

Now, you must have a deeper understanding of gantry truss crane. And you must know how to choose the truss cranes to improve the work efficiency.

If you want to know more about overhead cranes, gantry cranes, jib cranes, port cranes or crane parts, contact our technicians and business managers. We will offer you professional guidance and support.