Products

Flexible Single Girder Workstation Crane

Flexible Workstation EOT Crane

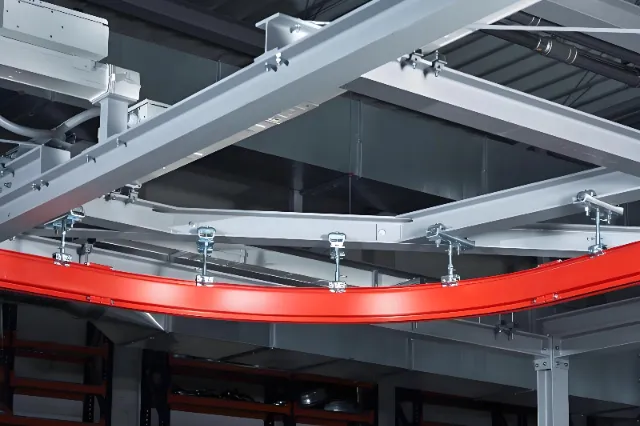

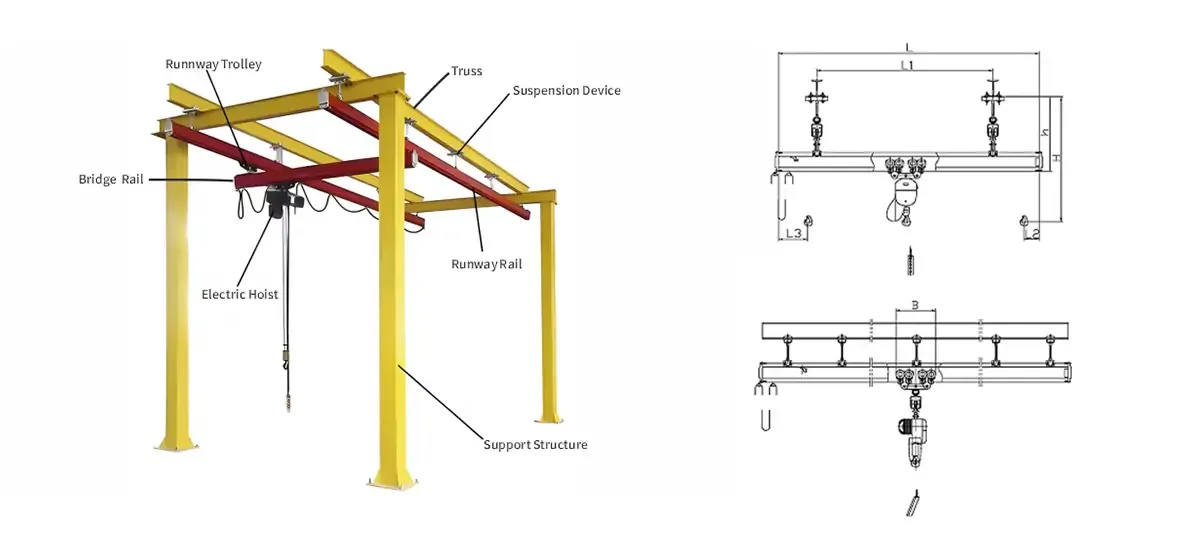

Flexible combined workstation crane is a modular light lifting equipment, especially suitable for working environments that require flexible handling and precise operation. Its main structure includes track system, suspension device, mobile trolley and lifting mechanism. The track system consists of standardized the freestanding tracks, which can be flexibly arranged according to actual needs to form straight or curved paths, and even multi-layer layout can be achieved. The suspension device fixes the track to the top structure of the plant through the boom to ensure the stability and safety of the entire system.

The mobile electric trolley is one of the core components of freestanding workstation crane system. It runs along the track, carries and moves the load. With a manual or electric drive device, it ensures easy and efficient operation. The lifting mechanism is responsible for material handling in the vertical direction, and common forms include chain hoists and wire rope hoists. These components work together to enable the flexible combined workstation crane system to cover a wide range of operations and provide precise position control.

In addition, the modular design of the workstation system makes installation and maintenance simple and fast. And users can easily adjust or expand the system configuration according to changes in production needs. This flexibility not only improves work efficiency, but also reduces long-term operating costs, making it an ideal material handling solution in many light industrial fields.

The Flexible Combined Workstation Crane is a compact, adaptable lifting system for light-duty (0.5–3.2 tons) workshop tasks. It’s ideal for assembly lines/warehouses, balancing flexibility and safety. It has five following core components:

| Item | Data |

| Capacity | 0.5-3.2 ton |

| Span | 0.7-12 meter |

| Lifting height | 3-12 meter |

| Lifting speed | 1-22 m/min |

| Travelling speed | 3.2-40 m/min |

| Power source | as your demands |

| Other Dimensions | According to your specific usage, specific model and design will offer |

Dafang supplies high quality overhead cranes, gantry cranes, jib cranes, electric hoists and crane spare parts etc. You can fill out the form below, and we will contact you as soon as possible

Stella