Get in Touch

Stella

News

An overhead bridge crane is a type of material handling equipment to lift and move heavy loads horizontally. It is a robust lifting equipment for use in factories, workshops, and other industrial settings. An overhead bridge crane is famous for its bridge-like shape. It can meet customers' specific needs of daily loading operations.

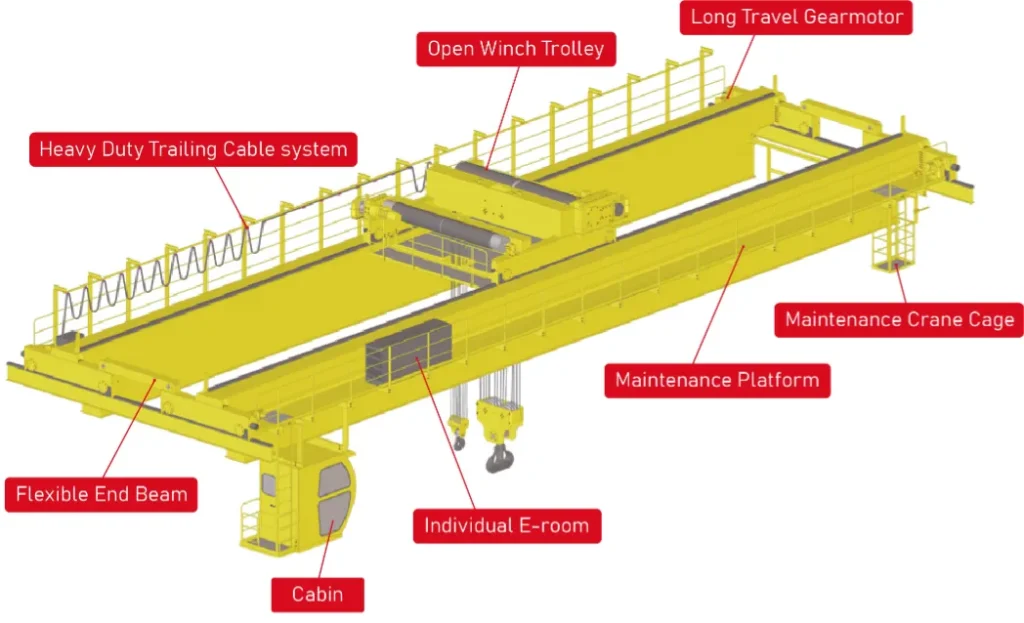

An overhead crane consists of parallel runways with a traveling bridge spanning the gap, along which a hoist moves laterally. The crane operates on three axes: the bridge travels along the runway beams, the trolley runs across the bridge, and the hoist lifts the load vertically. The crane can be manually operated or powered electrically on demand. In addition, clients can customize special solutions according to load and span needs.

Compared to ground-mounted or ground-based equipment, overhead cranes save floor space and enable faster operations in workshops. Clients operate overhead cranes for handling materials, lifting molds from press machines, and transferring raw materials to production lines. Commonly in industrial factories, warehouses, and shipyards, these bridge cranes maximize floor space efficiency and improve safety by reducing manual lifting. They notably enhance productivity in manufacturing and assembly operations. What is more, in high-risk environments involving high-temperature metals, chemicals, or toxic substances, overhead cranes provide a safer method of material transportation to reduce risks for workers.

Overhead cranes differ in size, type, design, and configuration, with a wide range of components and spare parts. Here is a brief table of different types of overhead cranes.

| Type | Name | Features |

|---|---|---|

| General Type | General Overhead Bridge Crane | Adopt CD/MD Electric Hoist/European Hoist Trolley |

| European Type | European Overhead Crane | Adopt European Type/Low Headroom Electric Hoist |

| Freestanding Type | Freestanding Bridge Crane | Rigid One/Flexible One Optional; Adaptable integration into a complete framework system |

| Suspension Type | Suspension Running Crane | Lightweight design, space-saving, smooth operation, suspended from overhead beams |

| Workstation Type | Workstation Bridge Crane | Compact structure; Multiple devices can be integrated into a complete system |

| Special-purpose Type | Special-purpose Overhead Crane | For high-risk environments, high-temperature metals, chemicals, toxic substances, or waste disposal |

General Overhead Crane is a common lifting equipment in industrial settings, with a robust bridge, two fixed tracks, and a trolley with hoist. It runs on runways, enabling horizontal and vertical movement of heavy loads across large areas. Available of 1-32T (single beam), 5-800T (double beam), it ensures high reliability, safety, and productivity in factories, warehouses, and workshops.

European overhead cranes are handy lifting tools. They have two types: single-beam and double-beam. Single-beam European ones are light-weight, good for lifting small loads, often paired with electric hoists. Double-beam European ones are stronger, for heavier loads, usually with trolleys. They have European compact structure so they can maximize space saving. Controls are precise and easy to operate, and they’re safe. Many industries like them for reliable lifting work.

Freestanding Bridge Cranes are a lightweight material handling system. Featuring aluminum alloy rails and standardized modular components, they’re super flexible. Customers can put them together and change their setup easily to fit different workshops, production lines, or warehouses.

They save effort, help work go faster, and are perfect for industries like electronics, car making, and machine factories. They work smoothly with precise positioning in assembly lines, warehousing, and maintenance scenarios.

They are adaptable to integrate into a complete framework system in a warehouse. By achieving assembly-line style work to reduce manual effort, they boost work efficiency and lower labor intensity.

A Suspension Running Crane is a lifting device with rails installed on building roofs or the lower chord of a steel structure. It includes a main beam, a suspended traveling device, and a lifting mechanism, thus achieving horizontal movement via the rails. It occupies no ground space, operates smoothly, and can handle a wide range of loads. Customers use it in industrial plants, warehouses, and logistics centers to complete cargo lifting and transfer operations.

Workstation Bridge Crane is a type of bridge crane for light to heavy production tasks. Workstation cranes typically are single girder EOT cranes. They are small, flexible lifting tools, perfect for use near workbenches or production lines. They are compact and customizable to fit specific workspaces. They’re easy to install and move. You can adjust their position to fit where you work.

They help move things quickly, saving time and making work easier. Many factories use them for daily small lifting jobs. And their ergonomic design stands out. This design reduces the need for manual lifting of heavy materials. This not only enhances worker safety but also boosts morale, improves quality, and increases productivity.

Special-purpose cranes are made for tough jobs and special tasks. They almost are double girder EOT cranes. They work well in hard conditions, handling things like bulk materials, dangerous areas, and high-voltage work. They’re reliable for industries like mining, power, and chemical plants.

Grab bucket cranes have claws to move coal, ore, or grain easily in ports or mines. Electromagnetic ones use strong magnets to lift steel things, with backup power to keep loads safe. Explosion-proof cranes have parts that don’t catch fire, good for places with flammable gas or dust. Insulated ones use safe materials, perfect for working near live power lines. These cranes are strong and fit many needs. They boost work speed and keep workers safe, making them great for important industrial jobs.

How do you choose your most suitable type? Now, you will deeply learn about the main types of overhead cranes. Overhead bridge cranes have two structural types: single beam overhead crane and double beam overhead crane. Single-beam cranes use suspended trolley cranes, while double-beam cranes use double-beam crab trolley cranes. Both types can be configured for top-running or bottom-running operations.

From these two basic types, there are numerous crane sizes with variations in capacity, configuration, and function. Selecting the right crane involves careful consideration, as the appropriate choice and specifications can significantly enhance productivity, efficiency, and workflow. Next, let us think about it together.

Selecting the right overhead crane requires aligning three core factors with your specific needs: load characteristics, spatial constraints, and operational demands.

By balancing these elements, you’ll select a crane that maximizes safety, productivity, and longevity. When selecting the most suitable bridge crane, you need to evaluate the following three key factors: load requirements, environmental constraints, and operational needs.