Get in Touch

Stella

News

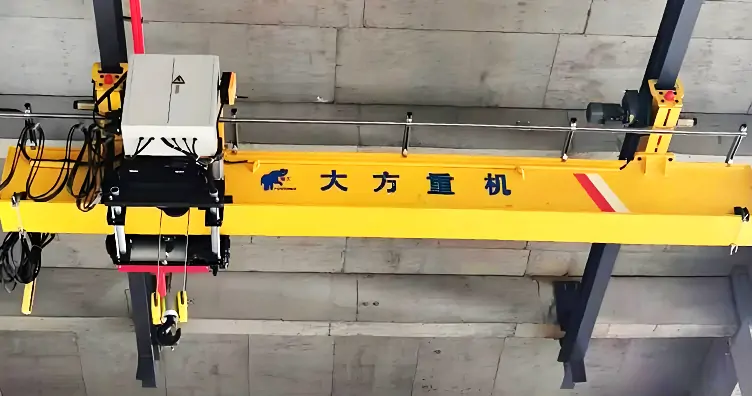

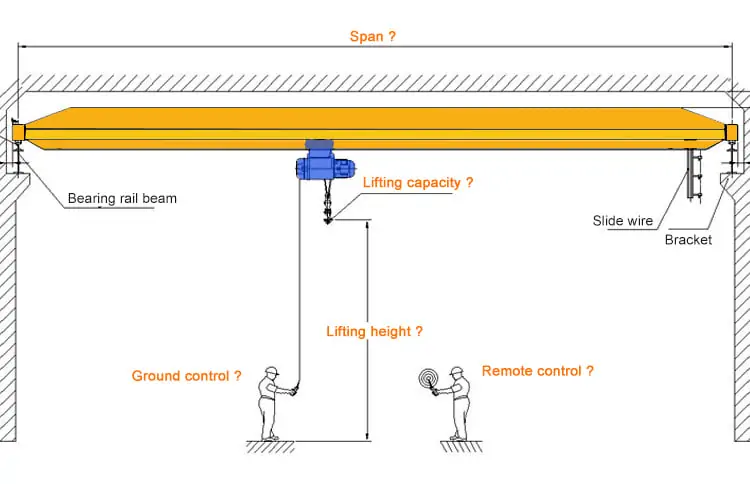

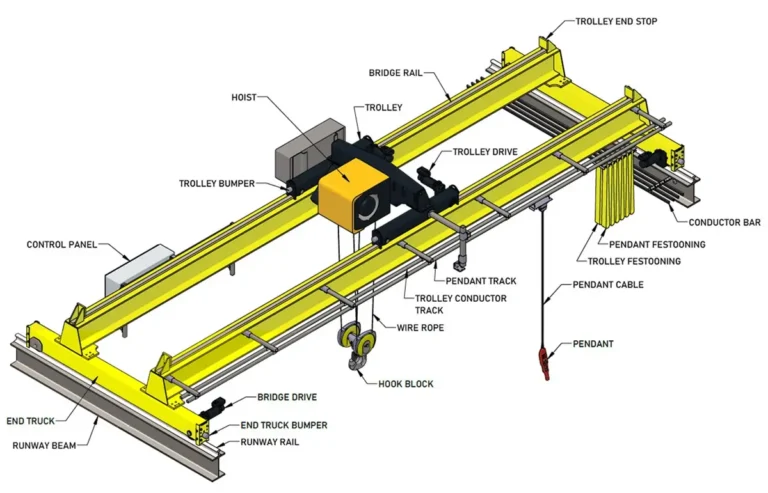

An overhead crane, or bridge crane, is a crucial industrial lifting solution for heavy-duty handling. It features a bridge-shaped main girder supported by end trucks on overhead rails, with a hoist trolley that moves vertically and horizontally to lift and transport loads. In daily life, an overhead crane is widely used in manufacturing factories, warehouses, workshops, harbors, etc. Available in single-girder type (for lighter loads, 1-20 tons) or double-girder type (for heavier tasks, 5-500 tons), an overhead crane optimizes industrial workspace utilization by leveraging overhead space.

Here, an overhead crane is introduced in detail, including its definition, structure and components, working principle, application, specs etc. This article will make you learn more info about an overhead crane for your needs.

Single Girder Overhead Crane

40 Ton Double Girder EOT Crane For Sale

An overhead crane, also known as a bridge crane, is a heavy-duty lifting equipment specifically for industrial load handling. It is installed above workspaces like factories, warehouses, and manufacturing plants. It operates along fixed overhead rails, unlike mobile cranes that require ground space. It maximizes floor area for other operations while avoiding ground space waste. Designed to meet international safety standards (CE, ISO, EAC certificate etc.), it eliminates the need for manual handling of bulky items and reduces workplace injuries while boosting efficiency.

Its core structure consists of high-strength steel main girders, end trucks with frequency-conversion motors, a hoist trolley, and a hoisting mechanism equipped with brakes and wire ropes. It can handle loads ranging from light 1-32 ton (for small workshops) to heavy 500 tons (for heavy industry). The overhead crane has three flexible control methods: a cab (for complex operations with visual assistance), a remote control (for long-distance operation away from hazardous areas), or a handheld pendant (for close-range fine adjustments).

European Double Girder Overhead Crane

An overhead crane consists of main girder, end girder, trolley running mechanism, Overhead Travel Mechanism, hoisting mechanism, rail, cab, walking platform and other parts. The functional characteristics of each part are as follows:

Main Beam

End Beam

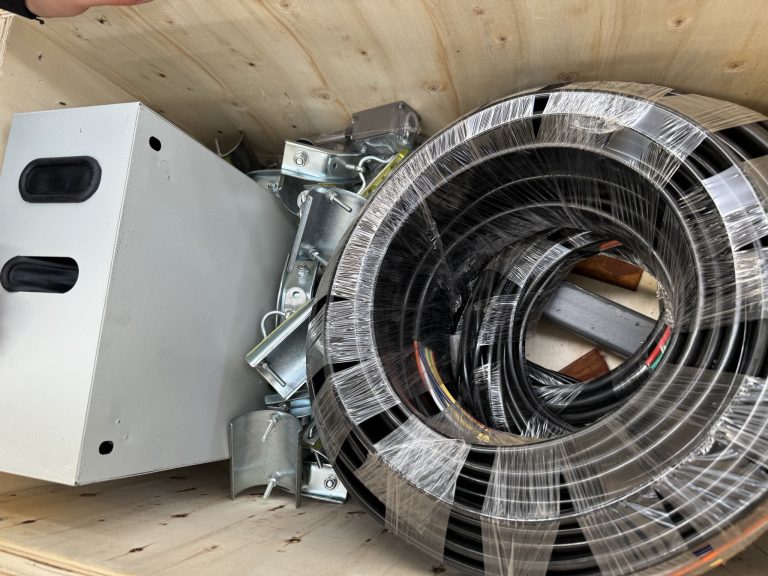

Motor and Cable

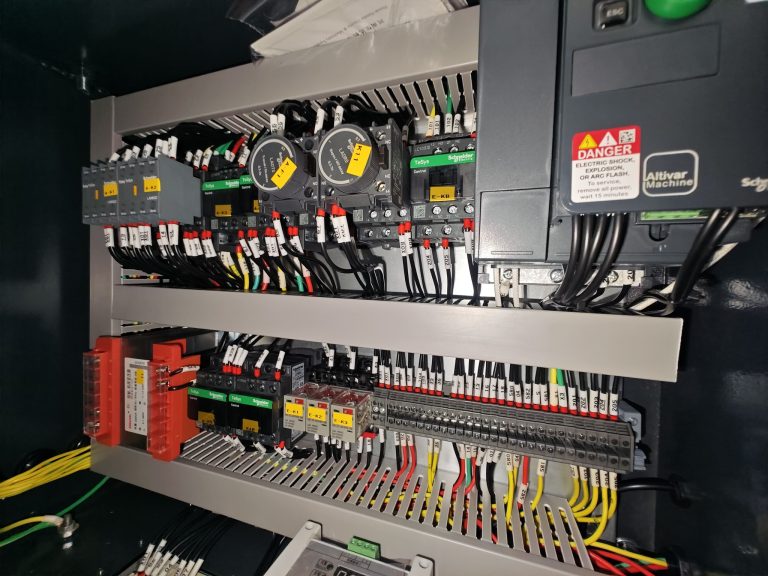

Electrical Control System

An overhead crane, stands as a linchpin in modern industrial material handling, facilitating the seamless movement of heavy loads within factories, ports, and warehouses.

Overhead cranes realize three-dimensional load handling through the coordinated operation of core components, relying on electric power and mechanical transmission.

Longitudinal Movement: The end trucks installed at both ends of the main girder are equipped with frequency conversion motors and driving wheels. When powered on, the motors drive the wheels to roll along the fixed overhead rails, enabling the entire crane to move back and forth across the workspace, covering the length of the operation area.

Transverse Movement: The hoist trolley is mounted on the guide rail of the main girder. Its built-in motor drives the trolley wheels to run along the girder. This allows the trolley and the hoisting mechanism to move left and right, thus covering the width of the operation area.

Vertical Lifting: The hoisting mechanism on the trolley consists of a motor, a wire rope drum, and a hook. The motor drives the drum to rotate forward or reverse, winding or unwinding the wire rope to lift or lower the hook, thereby completing the vertical movement of loads.

A cab room (remote or pendant control) controls all the movements with built-in brakes and overload protection to ensure stable and safe operation.

An overhead crane can move in a workshop, production line and warehouse to lift materials. There are different types of bridge cranes. And the features and application environments of different types are also different. Dafang Crane, as a professional overhead crane manufacturer and supplier, offers diverse overhead cranes. Such as single girder overhead crane, double girder overhead crane, suspension overhead crane, KBK light overhead crane etc.

If you want to choose the most suitable overhead crane to enhance productivity of your factory. The following article will bring you a comprehensive understanding of the different types of bridge cranes and their application scenarios.

Single Girder Overhead Crane

NLX Single Girder Overhead Crane

A single girder overhead crane is a lightweight industrial lifting device with a single main girder as its core structure, supported by end trucks running on overhead rail. It consists of a single bridge, two end trolleys, and a trolley hoist.

Typically, it has a lifting capacity of 1-32 tons, ideal for medium-light duty tasks. Its compact design uses less material than double-girder models, reducing installation and building load costs.

We often use single girder eot cranes in factories, warehouses, and workshops. They maximize floor space while meeting CE/ISO/EAC international safety standards. So single girder overhead cranes are cost-effective solutions for efficient material handling.

Double Girder Trolley Overhead Crane

European Double Girder Overhead Crane

The double girder overhead crane features two parallel steel main girders, for heavy-load tasks (20-500 tons) that exceed single-girder cranes’ capacity.

It consists of two bridges, two end cars and one or two trolley hoist assemblies. The trolley hoist travels on tracks mounted on top of the bridges. Its dual-girder design boosts stability, minimizing deflection when lifting ultra-heavy items like steel coils or ship hull parts.

Among them, the European double girder bridge crane is an important material handling equipment. Users prefer to choose them because of their simple structure, good stability, smooth operation, and large lifting capacity.

Customers often use them in industrial and mining enterprises, steel and chemical industries, etc.

LX Suspension Overhead Crane

A suspension overhead crane is a space-saving lifting device. It is installed by hanging its end trucks directly from a building’s roof load-bearing beams, no ground support columns or rails needed.

It has a compact structure, wide coverage range and high space utilization. It typically has a load capacity range of 0.5 to 20 tons.

Users often apply them for small workshops, electronics factories, and logistics warehouses.

Flexible Single Girder Workstation Crane

KBK Rigid Single Girder Overhead Crane

KBK Light Overhead Crane is a compact, efficient lifting solution for light-duty tasks (0.5-10 tons), widely used in small workshops, assembly lines, and logistics areas. It has two main types:

An Overhead crane is mainly used for material handling and has a variety of functions to efficiently accomplish the loading, unloading, handling, and stacking of goods.

Plants

Factories

Warehousing

Processing Lines

| Main Mode | HD/LX/LB |

|---|---|

| Lifting Capacity | 1-32 ton |

| Span | 3-31.5 m |

| Lifting Height | 6-30 m |

| Lifting Speed | 0.8/5m/min, 0.66/4m/min |

| Working temperature | -25℃~+40℃ |

| Power Supply | 3 Phase AC 380V 50HZ |

| Control mode | Remote Control/Pendant control/Cabin Control(customized) |

| Work Duty | A3-A5 |

| Main Mode | QD/QB/QZ/QC/QY |

|---|---|

| Lifting Capacity | 5-500 ton |

| Span | 10.5-31.5 m |

| Lifting Height | 6-32 m |

| Lifting Speed | 2-45 m/min |

| Working temperature | -25℃~+40℃ |

| Power Supply | 3 Phase AC 380V 50HZ |

| Control mode | Remote Control/Pendant control/Cabin Control(customized) |

| Work Duty | A4-A7 |

Notice: The items are only for reference. Customizable solutions are available.

| Types | Lifting Capacity | Price(USD) |

| Single Girder Overhead Crane | 1-32 ton | $3000 ~ $25000, depending on specifications |

| Double Girder Overhead Crane | 5-500 ton | $22000 ~ $1775000, depending on specifications |

| Suspension Overhead Crane | 0.5-32 ton | $2500 ~ $23000, depending on specifications |

| KBK Fliexible Overhead Crane | <5 ton | $1200 ~ $6000, depending on specifications |

Now, I am sure that you must have got a comprehensive understanding of overhead cranes and their working application environments. And you must know how to choose the most suitable types of overhead cranes to improve the work efficiency of your factory.

If you want to know more about gantry cranes, jib cranes, port cranes or crane parts, feel free to contact our technicians and our business manager. We will offer you professional guidance and support.