Get in Touch

Stella

News

Walking into a heavy-duty industrial factory or logistics warehouse, you will encounter an overhead travelling crane everywhere. An overhead crane is a large-scale suspended lifting equipment spanning the air. It can move loads of tens or even hundreds of tons smoothly. So it is an indispensable lifting machine in manufacturing, metallurgy, logistics, and other related fields. But how does an overhead crane work to accurately complete lifting tasks?

In this article, we will help you finger out the answer. Therefore, you can understand the working principle of overhead cranes. You can improve work efficiency and reduce manpower naturally.

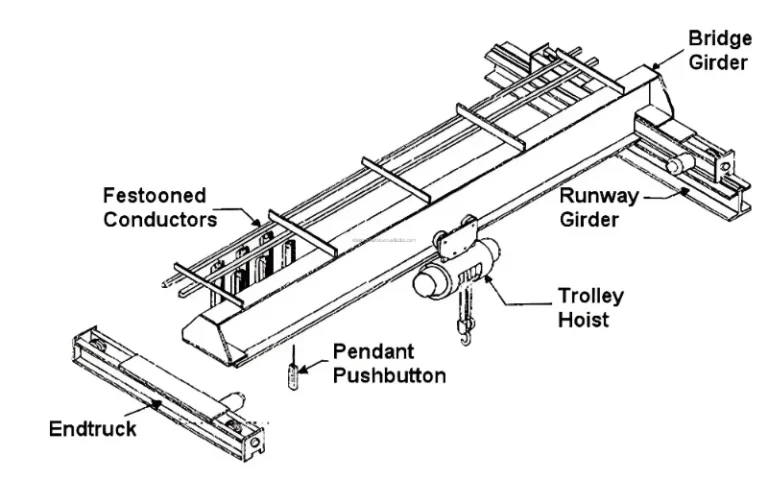

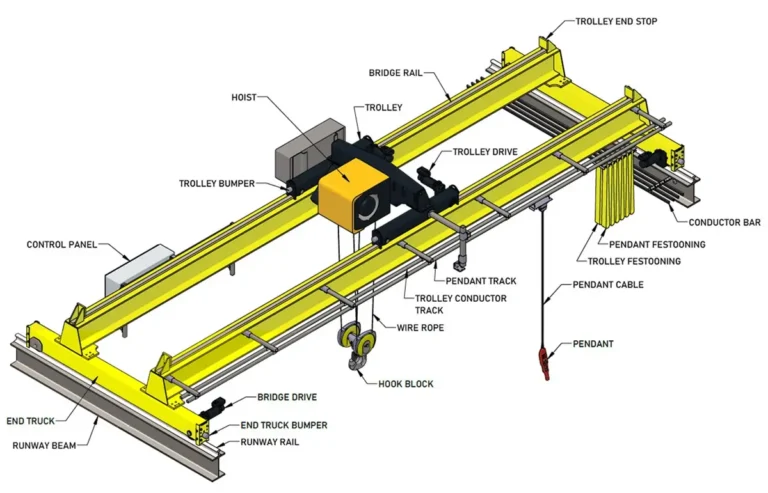

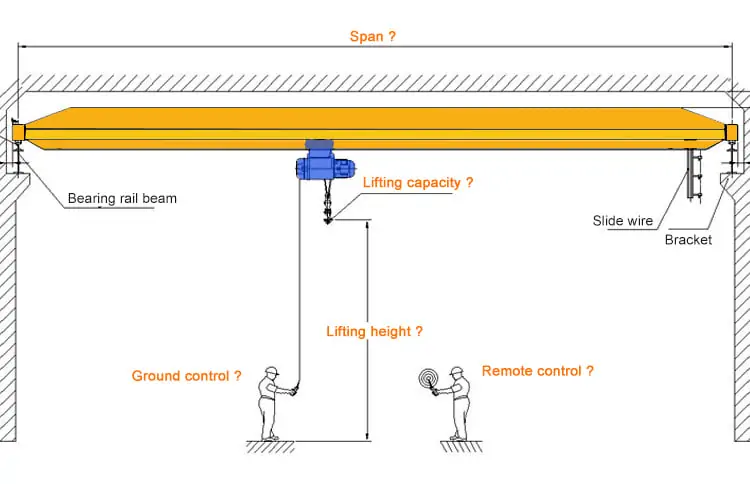

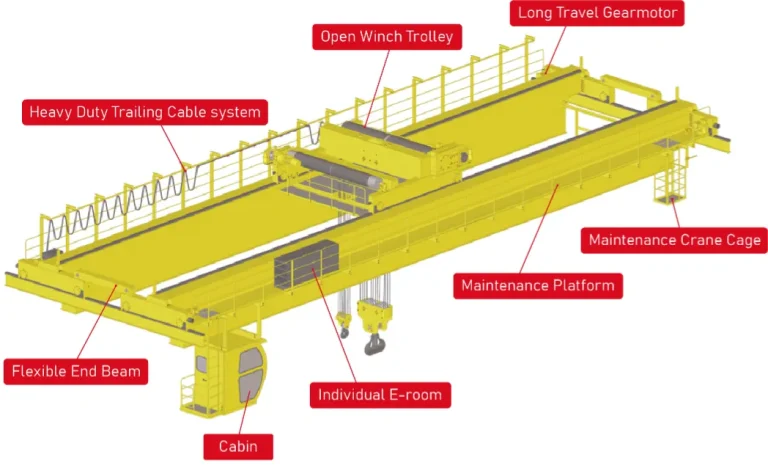

First, let us look at overhead cranes' structure and components. Therefore, we can better understand the working principle of overhead cranes from the mechanical structure, electrical control system, and operational process.

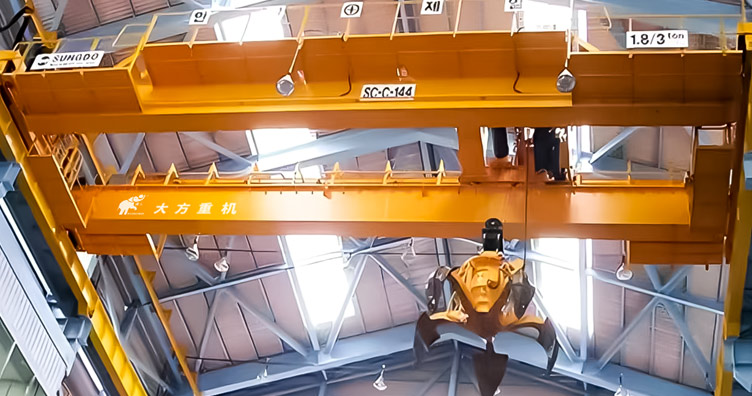

The core component is the main beam(s). Single girder overhead cranes have one main beam, while double girder overhead cranes have two main beams. The main beam(s) usually span(s) the columns on both sides of factories or workshops.

At both ends of the main beam(s), the end trucks match the workshop rails to form the “bridge travel mechanism”. This mechanism enables overhead traveling cranes to move along the length of workshops.

Below the main beam(s), there is an electric wire rope hoist/electric chain hoist or a suspending hoist trolley. The core power component, an electric hoist with steel ropes and a lifting hook, is responsible for lifting and lowering loads. The hoist and the trolley can slide horizontally along the main beam.

Additionally, the electrical control system supports handle or remote control. Double girder bridge cranes have a driver's cab. Users make use of the system to command the coordinated operation of all overhead crane components.

The working process of overhead bridge cranes has three main steps. The first step is “positioning”. The second step is “lifting”. And the third step is “transportation”. The following is a detailed introduction to the 3 steps.

1. “positioning”

The bridge travel mechanism: moving along the workshop rails

The trolley: sliding along the main beam

The hook: moving accurately above the loads

2. “lifting”

The hoist starts operating, and the steel ropes retract or lower, driving the hook to lift the load stably.

During this process, an overload protection device conducts real-time monitoring to prevent equipment damage.

3. “transportation”

After lifting the loads, the bridge travel mechanism and trolley work together to transport the load to the target location.

Finally, the hoist lowers the load slowly to complete the entire lifting process.

An overhead crane is a key lifting equipment in industrial scenarios. Clients mainly use overhead EOT cranes to move, load, unload and transfer heavy materials. It has two main types: single-girder and double-girder types. They have different application scenarios based on different load capacity and working conditions.

Single girder overhead crane has a simple structure and light weight. Therefore, it is suitable for light and medium-duty operations (usually load ≤32 tons). Our Customers often adopt them in small and medium-sized factories, warehouses, and workshops. They make use of single beam overhead cranes to handle small parts, finished products, or raw materials. For example, they use them to transport auto parts and engine blocks in assembly workshops or stacking goods in logistics warehouses.

Double girder overhead crane has a more stable structure and stronger load capacity (usually load ≥10 tons, up to hundreds of tons). Users mainly apply them in heavy industries like steel mills, shipyards, and power plants. They use double beam overhead cranes to lift heavy materials such as high-temperature steel billets, ship sections, and large mechanical equipment. Our high-quality double beam bridge cranes can meet customers' high-intensity and high-precision lifting needs.

To ensure the long-term stable operation of an overhead crane, regular inspections and maintenance are essential.

1. Routine inspection items include checking the appearance of wire ropes (for cracks, wear, or deformation) to test the sensitivity of the operating handle and remote control. At the same time, we need to confirm that safety devices are functioning normally, such as overload protectors and limit switches.

2. For regular maintenance (usually monthly, quarterly, or annually), it is necessary to lubricate key components. These components include trolley wheels and hoist bearings. In this process, we need to inspect the tightness of connecting bolts on the main beam and end beams. And we should test the insulation performance of the electrical control system.

3. When faults occur (such as abnormal noise during operation, slow lifting speed, or braking system failure), we should shut down the overhead crane immediately. Specialist maintenance personnel must identify the fault sources and carry out repairs or component replacements promptly. For example, they need to check if the gearbox is short of oil when there is abnormal noise. And they should inspect the brake pads for wear when braking fails.

4. After maintenance, we must conduct a test run to ensure the equipment to resume normal working condition before it is put back into use.

With the advancement of industrial intelligence, many overhead cranes are now equipped with remote monitoring and automatic positioning functions. This not only simplifies operation but also enables real-time monitoring of equipment status. They can provide data support for early fault detection and planned maintenance. However, we must not overlook the importance of regular inspections. This helps minimize costs associated with equipment damage, repairs, and replacements.