Prendre contact

Stella

Actualités

Overhead bridge cranes are essential industrial lifting systems. They consist of a horizontal girder mounted on runway beams. They can ensure efficient horizontal and vertical movement of heavy loads. They play a critical role in manufacturing, logistics, and construction by enhancing productivity. They can ensure safety and optimize space utilization.

This article explores key types of overhead bridge cranes. We will highlight their design variations, load capacities, and application scenarios. Understanding these distinctions can help customers better select the optimal overhead crane type. Choose the overhead cranes applying with operational demands, safety standards, and cost-effectiveness.

A bridge crane is a simple yet powerful lifting device. It consists of two fixed tracks, a bridge girder spanning the tracks and a moving trolley and hoisting mechanism system. These components work together to efficiently lift and move cargo. Two tracks are fixed on either side of the building. These tracks are securely connected to the building's upper structure to ensure stability. A bridge spans these tracks, serving as the crane's main structure.

General overhead bridge cranes have single girder overhead cranes and double girder overhead cranes. Single girder models have a compact structure, low manufacturing cost, and easy operation.They are ideal for light-load ( ≤20 tons) and small-span (within 22 m) scenarios like small workshops and warehouses. Double girder cranes offer higher load capacity, larger spans, and stronger stability. They are suitable for heavy-duty, high-precision operations in large factories, ports, and steel mills. Their design differences directly determine application range and operational efficiency.

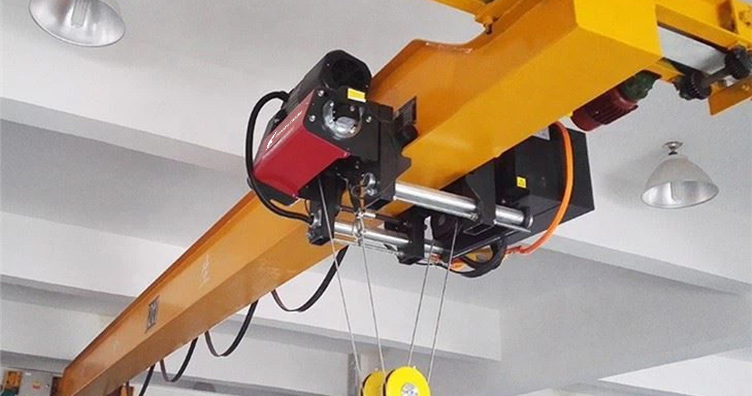

A suspension overhead crane is a highly efficient material handling device. It consists of a bridge frame, cantilever, hoist trolley, and control system. The bridge frame is suspended from the building structure via tracks. The cantilever can move horizontally along the tracks, working in conjunction with an electric hoist or gripper to achieve precise lifting and handling in three-dimensional space.

This model is suitable for medium to low-intensity operational environments such as workshops and warehouses. It offers advantages including a compact structure, wide coverage range, and high space utilization. The typical load capacity ranges from 0.5 to 20 tons. It supports multiple control methods including manual operation, wireless remote control, or cab operation. Safety features include overload protection and limit switches. In summary, the Suspension Overhead Crane is ideal for frequent loading and unloading of light to medium-weight materials.

European overhead cranes are efficient lifting equipment, split into single-girder and double-girder types. Single-girder ones are lightweight, good for light loads in workshops or small factories. Double-girder models are sturdier, handling heavier loads, often used in large factories or logistics centers.

They can pair with different tools: single-girder cranes usually work with electric hoists for quick, small lifts. Double-girder ones often use trolleys—these move smoothly along the girder, perfect for heavy or large items. Their structure is smart: compact design saves space, with precise controls for steady lifting. They’re also safe, with built-in protectors to avoid accidents. This makes them a top choice for many industries needing reliable lifting.

Freestanding KBK flexible cranes are modular light lifting systems, known for their flexibility and adaptability. Made of standardized components, they can be easily combined and adjusted to fit different workshop layouts or warehouse spaces. Ideal for light to medium-duty lifting tasks, they’re widely used in workshops, assembly lines, and storage areas.

These freestanding KBK flexible cranes are easy to install and reconfigure as needs change. They operate smoothly and ensure safe and efficient material handling. By reducing manual effort, they boost work efficiency and lower labor intensity. Perfect for industries like electronics, automotive, and machinery, they provide reliable lifting solutions for daily operations.

Workstation cranes are small, flexible lifting tools designed for use at workstations. They’re great for moving light materials frequently, like parts on assembly lines or small goods at workbenches. Easy to set up near where workers operate, they fit well in tight spaces.

These cranes have simple tracks and lightweight hooks. Workers can move them smoothly by hand, no heavy effort needed. They help lift things precisely, cutting down on manual lifting and making work faster. Safe and easy to use, workstation cranes are a go-to for factories or workshops where small, frequent lifts are part of daily tasks. They keep high work efficiency without taking up too much space.

Special-purpose cranes are advanced lifting solutions in extreme environments and specialized tasks. They integrate cutting-edge materials and safety features to handle bulk materials, hazardous conditions, and high-voltage operations. They can ensure precision and reliability across industries like mining, power and chemical plants.

Grab bucket cranes excel in bulk material handling, with hydraulic or mechanical claws designed to efficiently load/unload coal, ore, and grain in ports or mines. Electromagnetic cranes use powerful magnets to lift ferrous materials like steel coils and scrap metal, featuring emergency battery backup systems to prevent load drops during power outages. Explosion-proof cranes are built with flame-resistant enclosures and spark-free components, complying with standards like GB3836.1 to operate safely in flammable gas or dust environments. Insulated cranes utilize high-strength fiberglass structures and 220kV-rated insulation, enabling safe maintenance of live power lines and equipment.

These special-purpose cranes have high adaptability to fit diverse needs. From automating port logistics to ensuring worker safety in high-risk environments, they ensure heavy lifting for critical industrial applications.They boost work speed and keep workers safe, making them great for important industrial jobs.