Productos

Steel Mill Crane for metallurgy is an important lifting and transportation equipment for steel mill smelting workshop in steel industry. The crane mainly transfers liquid metal, pours and melts iron in the continuous casting process of steelmaking. The casting process maily refers to 3 stages. They include transfering molten iron to the converter across the converter charging, lifting molten steel to the refining furnace across the refining span and lifting molten steel to the continuous casting rotary ladle across the molten steel span.

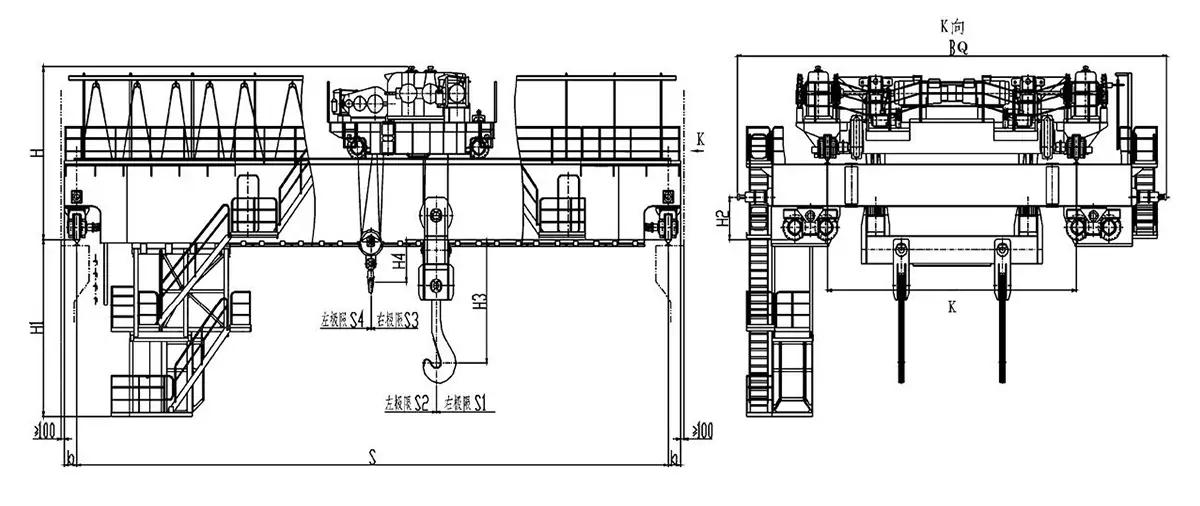

The structural design of Steel Mill Crane has various forms according to the tonnage and application requirements. The structure design mainly includes 3 common types. They are the double girder and double rail type, the four girders and four rails type and the four girders and six rails type. The Steel Mill Crane for metallurgy also has other types of structure. Among them, double girder double rail and four girder four rail structure is usually applicable to medium and large tonnage cranes. While the four girder and six rail double trolley form is mainly used for larger tonnage cranes.

Dafang metallurgy cranes have two types: YZ type and YZS type. The two are significantly different in structural design to meet the needs of different working conditions. YZ double girder type steel mill crane has capacity up to 125 tons, while YZS type four girder steel mill crane has capacity of more than 125 tons to meet higher load bearing demands.

YZ type steel mill crane for metallurgy adopts double girder and single trolley structure. It is mainly composed of bridge, trolley, hook beam, trolley running mechanism and electrical system. Main hook adopts a fixed-pitch hook beam. This hook is specially used for lifting steel ladle. The secondary hook works with the main hook to complete steel dumping, steel slag handling and other auxiliary lifting tasks. The operation mechanism and main electrical equipment are integrated inside the main girder, and the electrical room of the main girder is equipped with a chiller to ensure the stability of the equipment operation. The bottom of main girder is equipped with heat-insulating boards along the span direction, which effectively reduces the heat radiation effect of molten steel on the metal structure.

YZS type steel mill crane for metallurgy adopts the structure of main and vice double trolley, four beams and four rails. The crane mainly consists of bridge, main trolley, vice trolley, hook beam, trolley running mechanism and electrical system. The main trolley runs on the main girder track on the outside of the bridge and is responsible for lifting the ladle of molten steel.However, the vice trolley runs on the vice girder track on the inside of the bridge. It can traverse the underside of the main trolley and complete the tasks of molten steel dumping and slag handling through the hook and the main hook in cooperation. The running mechanism of the trolley adopts four-corner drive form to ensure smooth operation.

YZS Four Girder Steel Mill Crane

Our steel mill cranes for metallurgy take innovative technology, reliable performance, durable design, convenient maintenance as the core advantages. The following customized features are also available according to customer requirements:

| Lifting Capacity(t) | 200/50 | 225/65 | 240/80 | 280/65 | 320/80 | |

| Clase trabajadora | A7 | A7 | A7 | A7 | A7 | |

| Envergadura (m) | 28 | 27 | 22 | 21 | 24.5 | |

| Altura de elevación | Gancho principal | 26 | 32 | 25 | 24 | 28 |

| Auxiliary hook | 26 | 34 | 27 | 26 | 32 | |

| Velocidad | Gancho principal | 6 | 11 | 7 | 10 | 7.5 |

| Auxiliary hook | 10 | 11 | 9.6 | 12 | 10 | |

| Main Trolley | 41 | 41 | 35 | 30 | 29 | |

| Auxiliary Trolley | 38 | 39.5 | 38 | 39 | 39 | |

| Crane | 78 | 84 | 80 | 76 | 58 | |

| Dimensions (mm) | H | 6900 | 7000 | 7000 | 7600 | 7800 |

| H1 | 6000 | 5990 | 5650 | 6400 | 6500 | |

| H2 | 1650 | 1400 | 1350 | 1350 | 1500 | |

| B | 1700 | 17300 | 18500 | 19200 | 19500 | |

| B1 | 10000 | 10100 | 11250 | 12000 | 12500 | |

| B2 | 3200 | 3300 | 3800 | 3800 | 5000 | |

| Limit dimestion (mm) | b | 450 | 450 | 450 | 500 | 500 |

| H3 | 6000 | 5800 | 5500 | 5900 | 6000 | |

| H4 | 1000 | 1000 | 1500 | 1500 | 1700 | |

| S1 | 2600 | 2500 | 2800 | 3200 | 3300 | |

| S2 | 3000 | 3000 | 3200 | 3500 | 3500 | |

| S3 | 2000 | 2200 | 2400 | 2400 | 2600 | |

| S4 | 1600 | 1600 | 2800 | 2800 | 3000 | |

| Max wheel load(kN) | 530 | 550 | 545 | 595 | 650 | |

| Steel track recommended | QU120 | |||||

| Power source | 3-Phase A.C. 380V 50Hz | |||||

Every steel mill is unique, and so are the challenges it faces. That's why Dafang offers fully customized YZ steel mill cranes that seamlessly integrate into your existing operations to maximize your productivity. Contact us today for a free consultation!

Dafang supplies high quality overhead cranes, gantry cranes, jib cranes, electric hoists and crane spare parts etc. You can fill out the form below, and we will contact you as soon as possible

Stella