Liên hệ

Sao

Tin tức

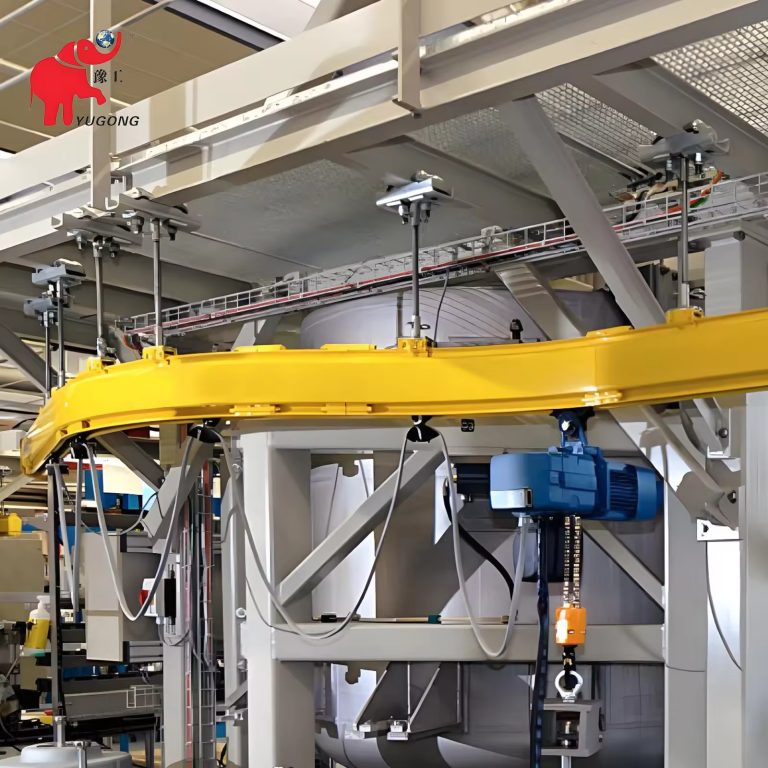

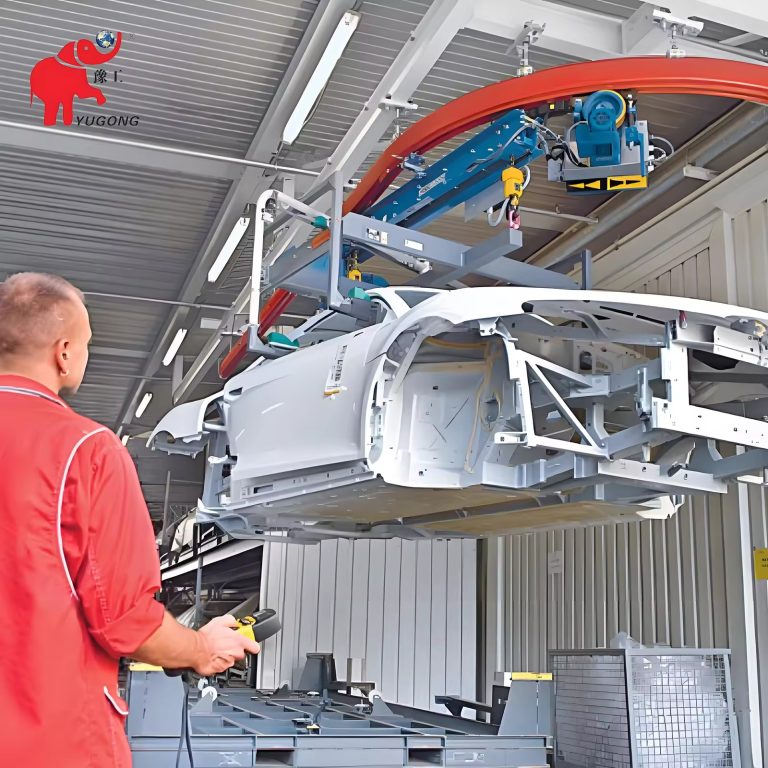

In modern material handling, monorail cranes are essential for efficiently lifting and transporting heavy loads. Dafang Crane provides low-cost but high-quality, good-performance monorail cranes. They feature streamlined design and focused functionality. Therefore, they perform well in industrial, warehouse, and workshop operations.

Let’s explore their definition, features, application and differences with other common or underslung bridge cranes. Lastly, we will give you guidance and tips to choose the right cranes to improve productivity and efficiency.

A monorail crane is a special lifting system operating along a single, fixed rail. It combines a hoist (electric or manual) to lift loads. The electric hoists can lift goods horizontally along the rail’s linear path with precision. Unlike multi-rail systems, monorail cranes prioritize simplicity and target movement. So they are ideal for applications that require controlled, straight-line material handling.

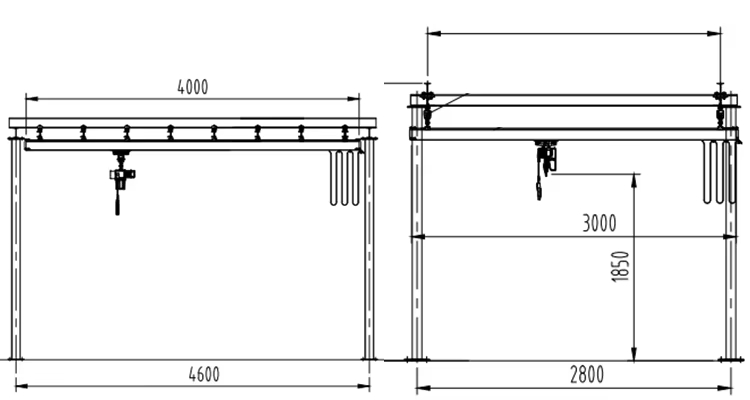

Monorail cranes consist of a single rail (typically steel or aluminum material) as the travel path, a trolley/carrier with a hoist (chain, wire rope, etc.) for lifting/moving loads, lifting attachments (hooks, slings), and may also include main beams, end beams, and an electric control system for efficient operation.

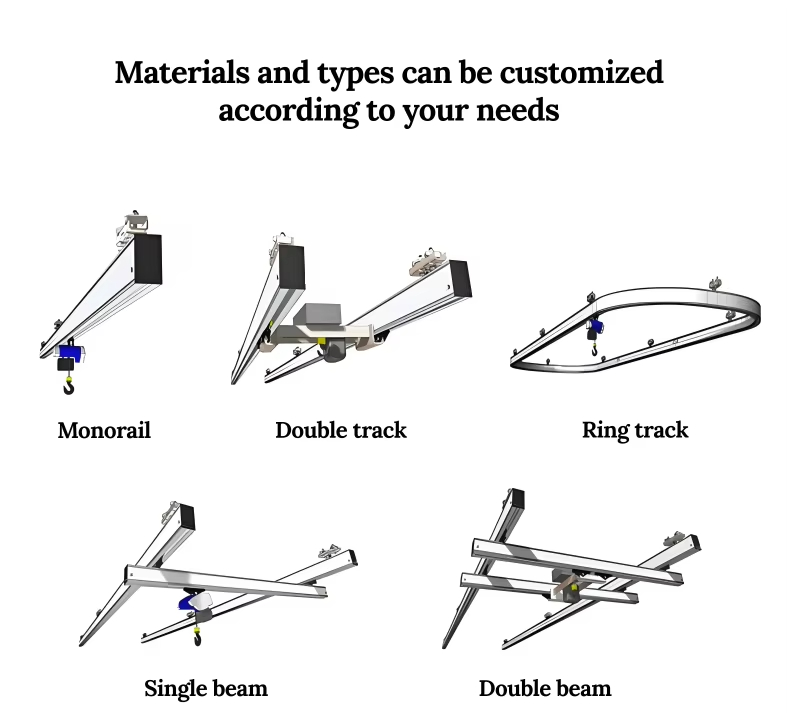

The monorail light crane is a modular crane with a typical load capacity < 2 tons. Monorail crane primarily consists of rails, suspension units, lifting mechanism and other functional components. Clients can freely assemble all standardized module parts for unique factory requirements. Using Dafang monorail cranes, they can precisely, swiftly and efficiently meet your specific application requirements.

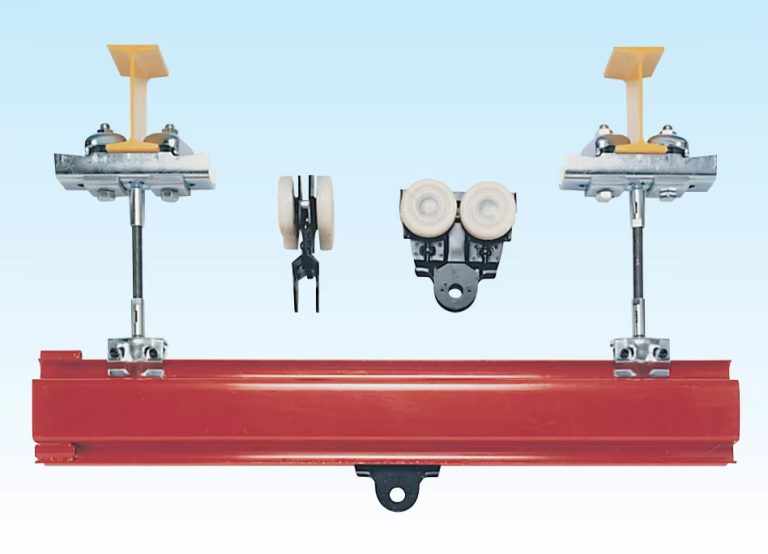

Articulating suspension: Significantly reduces horizontal forces on roofs and supporting superstructures.

Main Beams: Offer extensive design flexibility to accommodate diverse requirements.

Running wheels: Provide smooth operation with low noise levels while reducing overall crane weight. They also exhibit corrosion resistance and wear resilience.

| Product | KBK Bridge Crane |

|---|---|

| Sức nâng | 0.5-2 tons |

| Khoảng cách | 7.5-31.5 m |

| Chiều cao nâng | 6m/9m/12m/18m/24m/30m |

| Power Supply | 380V 50Hz |

| Control Method | Wire-type control + radio remote control |

| Nhiệm vụ công việc | A3 |

| Feature | Monorail Crane | Common Overhead Crane | Underslung Crane |

|---|---|---|---|

| Rail Structure | Single fixed rail | One or two bridge main girders | Suspended from an overhead runway beam |

| Movement Range | Linear range (along the rail) | Covers a rectangular area | Linear range (along the suspended runway) |

| Space Occupancy | Minimal (compact structure design) | More than two other types (need space for main beam and trolley) | Depends on ceiling height or way of runway placement |

| Typical Load Capacity | Lower (often < 5 tons for standard models) | Higher (5–320 tons, even 500 tons) | Medium to high (commonly 2–20 tons) |

2. Benefits & Effects:

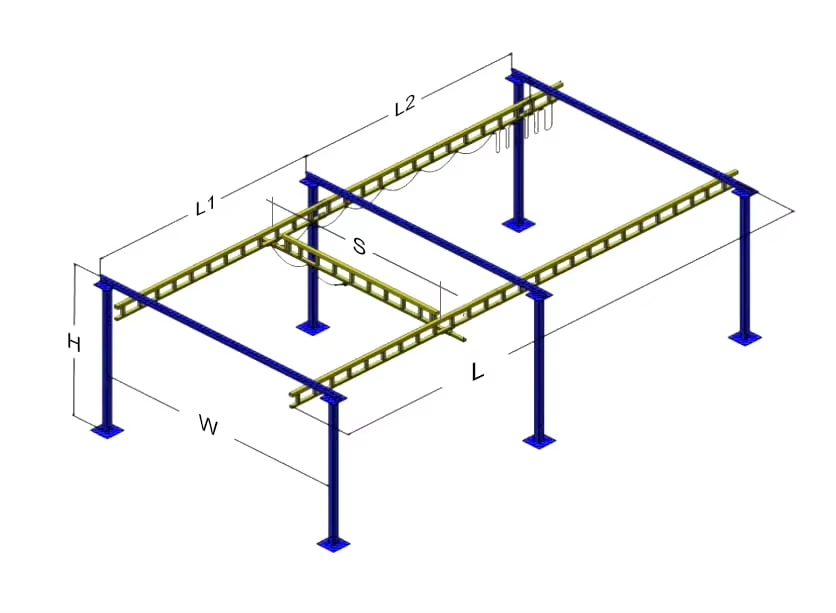

To get the properest monorail crane quotation, the following information regarding your specific requirements and crane operating conditions must be provided.

The following key parameters are typically required by Monorail crane manufacturers or suppliers to generate quotations:

After reading this essay, you must have a better understanding of Monorail overhead cranes. And you get the overhead crane selection guidance and tips to choose the right crane to improve work efficiency.

At Dafang Crane, we offer the free consultancy services and one-stop services. What is more, if you want to know more about gantry cranes, port cranes, overhead cranes, jib cranes, bridge construction quipment or crane spare parts, just feel free to contact our technicians and business managers. We will offer you the most professional guidance and support.