Liên hệ

Sao

Tin tức

In construction sites or port terminals, using a right crane is important for work efficiency and operation safety. Two common choices are available—RTG Cranes (Rubber Tyre Stacking Cranes) and RMG Cranes (Rail Mounted Stacking Cranes). Both of them have their own distinct advantages and disadvantages. Rubber Tyre Gantry Crane and Rail-mounted Gantry Crane are core equipment for container yards, differing primarily in mobility and application scenarios.

RTG relies on rubber tyres for movement, adapting flexibly to temporary or irregular yards. RMG operates on fixed rails, delivering superior stability and efficiency for large-scale and long-term operations. RTG excels in versatility and low infrastructure costs, while RMG outperforms in load capacity, precision, and automation compatibility. Understanding the core differences between them can help businesses improve efficiency and productivity.

How to choose depends on aspects of yard size, operational needs, budget, and long-term development plans. Each dimension is important for tackling diverse requirements in port and warehouse operations. This article respectively details the definition, key features, key differences and the crane selection tips. We will guide you to select the best choice for your container operational requirements.

RTG Crane is a mobile container-handling equipment characterized by rubber tyres for locomotion. It requires no fixed rail infrastructure, enabling movement across yards without spatial constraints. Designed for medium-load operations, typical lifting capacities range from 40 to 60 tons, suitable for stacking 4–6 containers high and 6–8 wide. Its key advantage lies in flexibility. CLients primaraly apply this container crane for small-to-medium yards, temporary storage sites, or yards with irregular layouts.

RTG container crane is widely used in regional ports, inland container depots, and facilities with frequent layout adjustments. The installation process is very simple. And compared to RMG crane, it needs minimal upfront infrastructure investment. However, RTG crane also has little limitations: lower stability compared to RMG at high stacking heights, higher energy consumption (often diesel-powered drive), and reliance on skilled container gantry crane operators for precise positioning.

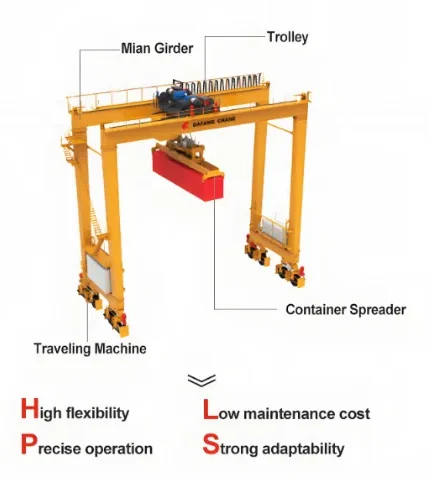

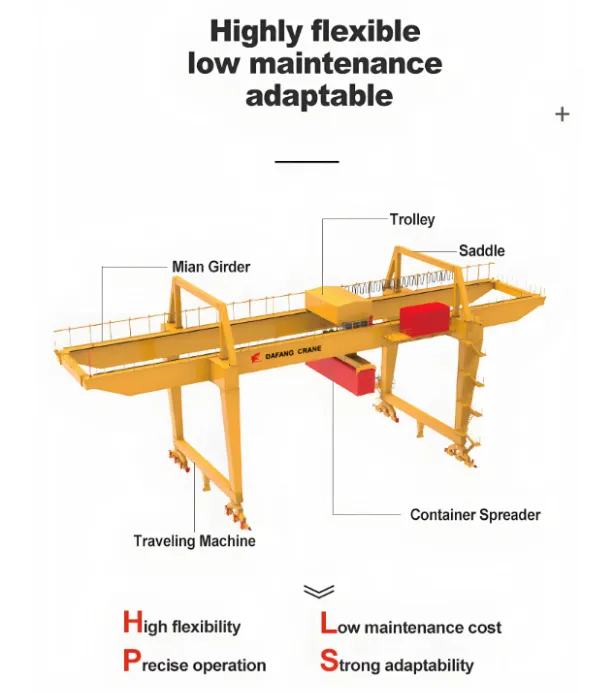

RMG Crane is a fixed-path container crane, running on dedicated steel rails. It excels for exceptional stability and high load capacity, typically 35–70 tons, supporting stacking heights of 6–8 containers and widths of 10–14 containers. Its unique rail-mounted design ensures precise positioning, making it highly compatible with automated systems. These advanced systems include BeiDou Satellite Positioning System, Laser Navigation, and remote control for unmanned operations.

RMG offers lower operational costs, as electric-powered models are energy-efficient and have reduced maintenance needs for rails versus tyres. Customers maily use it for large-scale, permanent container yards, deep-sea ports, and logistics hubs with high throughput. The little drawback is the high initial investment in rail infrastructure. And this rail design restricts mobility and requires fixed yard layouts compared to RTG crane.

| Dimension | RTG Crane | RMG Crane |

|---|---|---|

| Movement Mode | Rubber tyres (flexible mobility) | Fixed rails |

| Load Capacity | 20–70 tons (medium load) | 35–70 tons (heavy load) |

| Khoảng cách | 18-35 m | 18-40 m |

| Hook speed | 20-50m/min | 13-40m/min |

| Crane operating speed | 30-130m/min | 42-50m/min |

| Work duty | A5-A6 | A6-A8 |

| Site Requirement | No rails; adapts to irregular yards | Requires rail installation; fixed layout |

| Automation Compatibility | Low to medium | High (ideal for unmanned operations) |

| Operational Cost | Higher (tyre maintenance, fuel) | Lower (electric-powered, less maintenance) |

| Application Scope | Small-medium yards, temporary sites | Large ports, permanent high-throughput yards |

Selecting between RTG and RMG depends on the following core factors: First, assess yard size and layout: choose RTG for small, irregular, or temporary sites; RMG for large, permanent yards. Second, consider throughput and load: RMG is better for heavy loads (over 35 tons) and high-volume operations. Third, evaluate budget: RTG has lower upfront costs, while RMG offers long-term operational savings. Fourth, prioritize automation needs: RMG is the top choice for unmanned or semi-automated systems.

Both RTG cranes and RMG cranes are indispensable container lifting equipment. At Dafang Crane, we supply high-quality RTG container gantry cranes and RMG container gantry cranes. If efficiency, automation, and long-term reliable performance are your priorities, RMG crane is your ideal choice. If you have a little-scale working site and a tight budget to use it occasionally, thus RTG crane may be the optimal lifting solution.

Whether you need which lifting crane solution, Dafang's team will recommend and tailor the most suitable container gantry crane setup for your needs. Hope to reach further cooperation.