Liên hệ

Sao

Tin tức

Bridge cranes have different types, such as general type, suspension tyoe, European type, low-headroom type and monorail type etc. According to driving method (Hand or electric), there are 2 types of EOT cranes and HOT cranes. They have similar shapes and structures, but they vary in the driving methods, degree of automation and work efficiency.

In industrial and construction settings, selecting the right crane is critical for efficiency and safety. Two common options are Hand-Operated Travelling (HOT) Cranes and Electric Overhead Travelling (EOT) Cranes. Both of them have their own distinct advantages. HOT cranes, manually operated, offer simplicity and cost-effectiveness for lighter loads. Yet EOT cranes, powered by electricity, provide precision and higher capacity for heavy-duty applications.

Understanding their differences in load capacity, features, operation process and application scenes can help businesses improve efficiency and productivity. This article explores the definition, key features, structure and parts, ideal scenarios for both crane types and the crane selection tips. We will guide you toward the best choice for your operational needs.

HOT Cranes feature a simple structure with a single I-beam main girder and manual chain hoist. They rely on manual operation (push-pull or chain control) without electric drive systems, supporting lifting capacities of 0.5–5 tons. Ideal for scenarios like small workshop maintenance, warehouse temporary lifting, or explosion-proof/hopeless power environments, they have low maintenance costs (annual ~$200), quick installation (2–3 days), and suit low-frequency tasks (<10 times/month).

| Parameters | Technical Features | Typical Applications |

|---|---|---|

| Structural Design | Single I-beam main beam + manual chain hoist, no power drive system, light deadweight (≤1.5 tons). | Suitable for small workshop equipment maintenance and temporary warehouse lifting. |

| Lifting capacity | 0.5–5 tons (up to 10 tons available upon request). | Suitable for light parts handling and equipment maintenance. |

| Operation | Ground-level manual push-pull or chain control, no electrical system. | Suitable for power shortages or explosion-proof environments. |

| Maintenance Cost | Annual maintenance cost approximately $200, requiring only regular lubrication of the chain and rails. | Suitable for low-frequency use (<10 times/month). |

| Installation | 2–3 days, no specialized lifting equipment required, can be directly suspended from existing I-beam rails. | Suitable for renovation of old factories or temporary workstation deployment. |

| Reference Price (USD) | $4,500–$25,000 (basic model) |

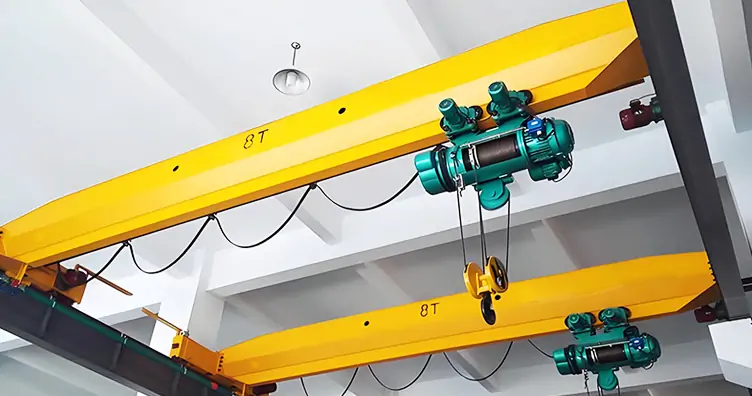

EOT Cranes are typically electric double-girder cranes, with a robust design of double box-girder main beams, independent electric trolleys, and frequency conversion control systems. They handle 5–250 tons (up to 500 tons for custom metallurgical models), operate via cabs or wireless remote control with multi-speed adjustment. Widely used in heavy industries like steel mills (molten steel ladle lifting) and ports (container handling), they offer high rigidity, precise positioning, long service life (20 years), and adapt to high-frequency, heavy-duty environments.

| Parameters | Technical Features | Typical Applications |

|---|---|---|

| Structural Design | Double box main girder and independent electric trolley, high rigidity (deflection ≤ L/800), equipped with a variable frequency control system. | Suitable for lifting ladles in steel mills and loading and unloading containers at ports. |

| Lifting capacity | 5–250 tons (up to 500 tons for metallurgy applications). | Suitable for heavy machinery manufacturing and nuclear power equipment installation. |

| Operation | Operated from the driver's cab or wireless remote control, with multi-speed adjustment (variable frequency drive). | Suitable for high-precision positioning requirements (such as loading and unloading CNC machine tools). |

| Maintenance Cost | Annual maintenance costs approximately $5,000, with regular inspections of the motor, reducer, and wire rope. | High-frequency operation (>50 operations/month). |

| Installation | 15–30 days, requiring specialized lifting equipment and a concrete foundation. | Suitable for deployment in new plant buildings or high-load structures. |

| Reference Price (USD) | $50,000–$500,000 (customized) |

| Dimension | HOT Cranes | EOT Cranes |

|---|---|---|

| Power system | Purely manual operation, no electrical power required. | Fully electric drive, equipped with variable frequency motor and control system. |

| Speed performance | Lifting speed ≤0.5 metres per minute; lateral movement relies on manual pushing. | Lifting speed ≤15 metres per minute; trolley travel speed ≤93 metres per minute. |

| Environmental Adaptability | Suitable for explosion-proof, humid, or high-temperature environments (e.g., chemical workshops). | Additional protective measures (e.g., heat shields, dust covers) required for extreme environments. |

| Energy Consumption | Costs Zero electrical consumption; labour costs only. | Annual power consumption about 5,000–20,000 kWh, dependent on load frequency. |

| Lifecycle | Design life 8–10 years. | Design life 20 years. |

Both EOT cranes and HOT cranes are indispensable tools for material handling. If efficiency, automation, and long-term reliable performance are your priorities, an EOT crane is your ideal choice. On the other hand, if you have a tight budget and a little-scale factory to use it occasionally, thus the HOT crane may be the optimal lifting solution.

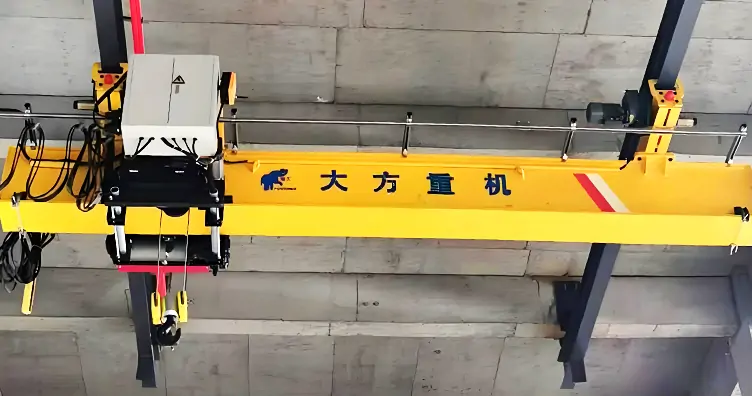

At Dafang Crane, we supply equally high-quality electric wire rope hoists or chain hoists and crane spare parts that can better support EOT crane and HOT crane operation. Whether you need good-performance lifting solutions or reliable manual handling systems, our expert team can help recommend and customize the most suitable crane setup for your needs. Hope to reach further cooperation.