Entrar em contacto

Stella

Notícias

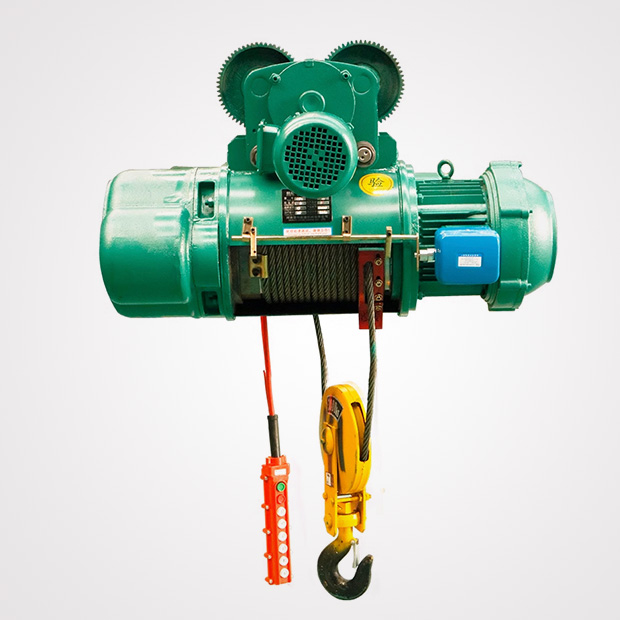

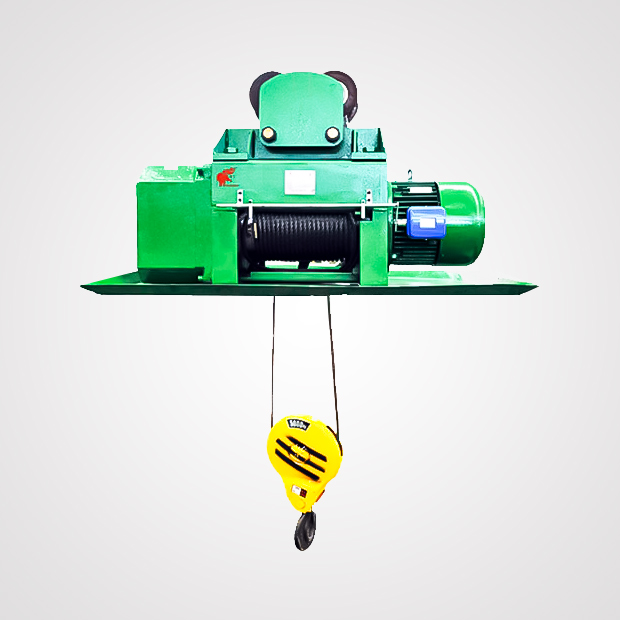

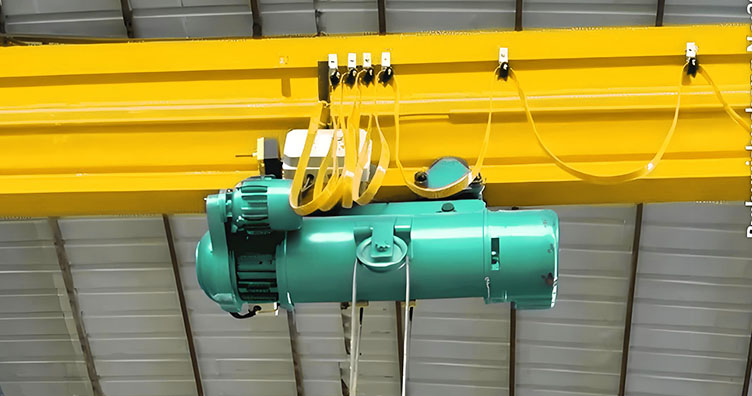

Looking for reliable and affordable lifting equipment? Dafang Electric Hoists stand out as a top choice. Dafang Crane offers diverse electric hoist models to meet varied needs: European, low headroom, standard headroom, metallurgical, explosion-proof, and dust-free wire rope or chain hoists.

What makes us stand out is the integration of smart management, precision manufacturing, and user-centric design. In this article, we will introduce the whole process of designing, manufacturing, processing, testing, packing and delivery of Dafang electric hoists in detail.

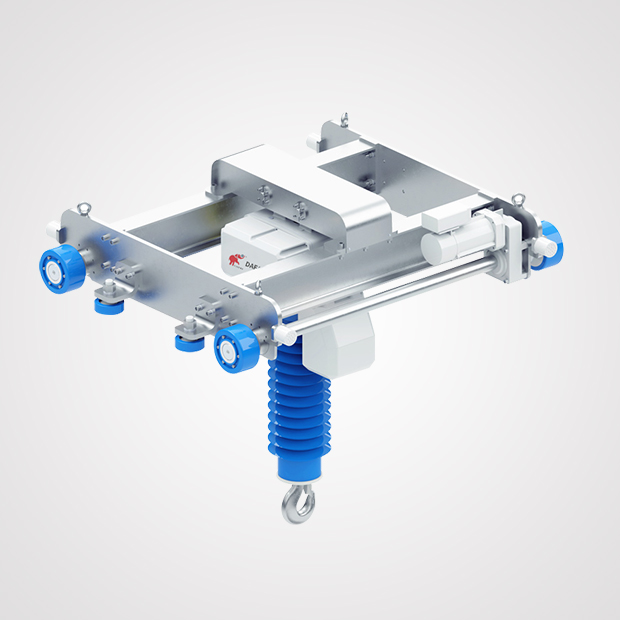

Our "smart brain" is the full-process informatization system (PLM+SAP+MES), covering the entire process from design to production. Engineers use 3D software for digital simulation, ensuring top quality even for non-standard products. During production, real-time data tracking covers assembly, inspection, and scheduling, leaving no room for errors in key links.

Dafang Crane's electric hoist manufacturing workshop consists of a hoist production assembly line and an automated paint spraying and drying line, with an annual volume of 30,000 electric hoists.

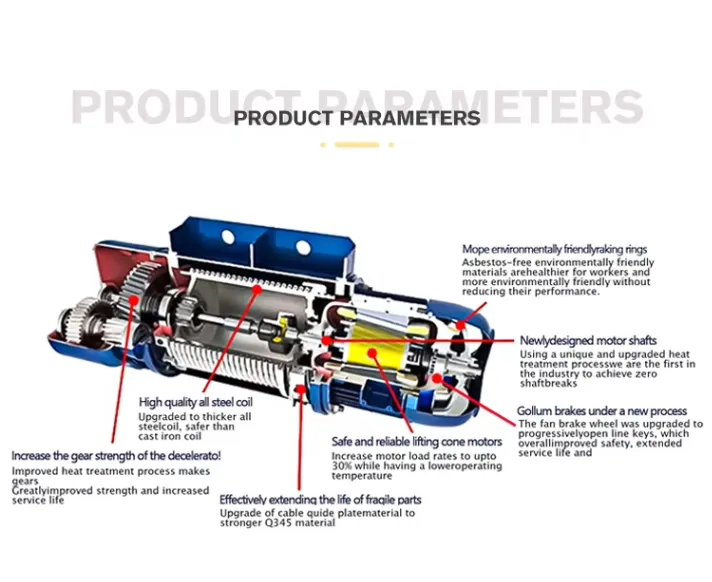

Precision manufacturing relies on advanced equipment: housing processing machines, CNC vertical machining centers, welding robots, turn-mill composite equipment, 30,000W laser cutters, 8-axis CNC dry-cut high-speed gear hobbing machines, and intelligent stereoscopic warehouses. High-precision testing tools like coordinate measuring machines, gear detectors, and micrometers guarantee consistent component quality.

Our electric hoists features their attractive appearance, reliable quality, low noise, and stable performance. The outer shell is 2 millimeters thicker than standard. Each employs a dual-flange structure to prevent wire rope from getting caught. Each assembled hoist undergoes an airtightness test with lubricating oil added before leaving the factory to ensure no oil leakage.

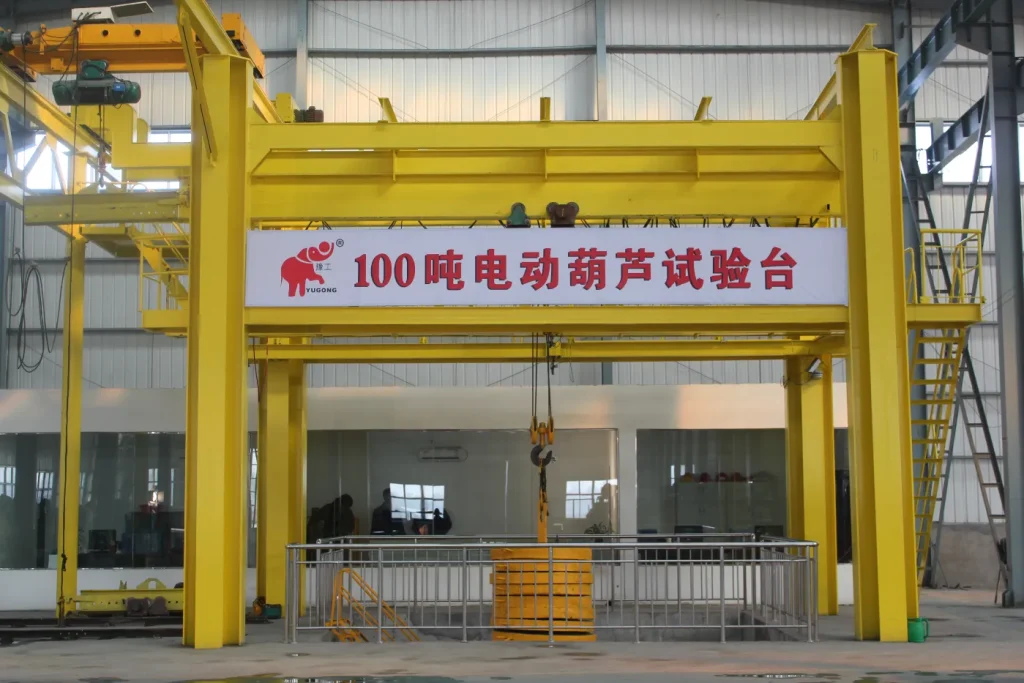

The hoist workshop has a leading 100-ton electric hoist test platform in China. Each hoist undergoes a 1.1 times dynamic load and 1.25 times static load test. The advanced baked paint production line not only enhances the lifespan of the product's paint but also improves its appearance.

The electric hoist workshop assembly line streamlines the whole manufacturing processes. It improves production efficiency, shortens delivery periods, cuts labor costs, and enhances product quality.

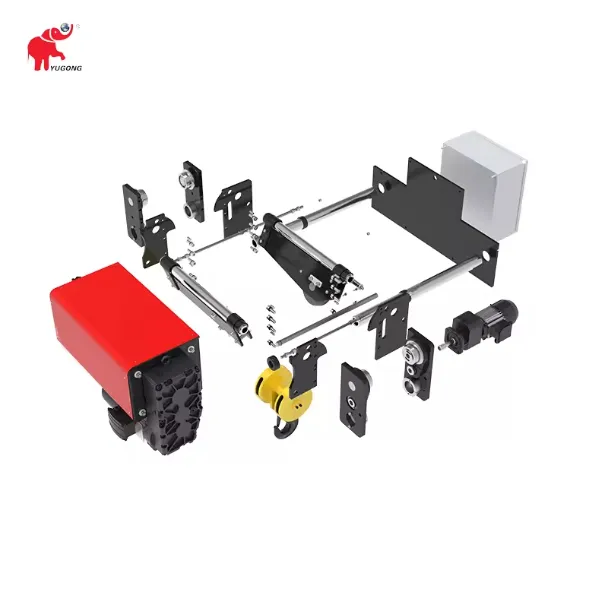

User-friendly configurations boost value. Eccentric frame plates for stable heavy loads; welded drums (with round steel and steel plates) for long service life; trolley side plates with high precision, thickened steel pipe joints; self-developed motors with aluminum casings for heat dissipation, thickened reducer casings (with 100% airtightness testing), ball iron rope guides (wear-resistant), pre-added lubricating oil, gravity steel safety cards (preventing hook disengagement), standard overload limiters, and 100m remote controls all enhance use performance.

Our company has established a 100-ton large hoist test platform, utilizing advanced simulation testing methods. Before finished hoist products leave the factory, professional technicians conduct comprehensive tests on electric hoists under both no-load and heavy load conditions, covering voltage, current, motor performance and noise. Only in this way can we ensure that all products leaving the factory pass the tests and confidently export them to our customers.

We use sturdy wooden boxes for packaging—main units, trolleys, and small parts are fixed separately. This considerate packing enables stackable storage for easy warehousing and safe transportation by land or sea.

Widely used across industries, Dafang Electric Hoists balance affordability and performance. Contact us now for your lifting needs!