Get in Touch

Stella

News

Gantry crane is a heavy-duty lifting device distinguished by ground-supported legs (unlike overhead cranes hung from roofs), with a horizontal main girder spanning between its legs. It handles 5-300 tons, suiting medium-to-heavy tasks. Available in single-girder type (for lighter loads, 1-20 tons), double-girder yard type (for heavier tasks, 5-800 tons), semi type or truss type.

Here, a gantry crane is explained in detail, including its definition, structure and components, working principle, application, specs etc. You learn more info about a gantry crane for your needs.

L Type Single Girder Gantry Crane

A gantry crane is a large outdoor lifting device with a door-shaped steel frame mainly for heavy-load handling. Comply with the international safety standards (CE, ISO, EAC etc.), it eliminates the need for manual handling of bulky items and reduces workplace injuries while boosting efficiency.

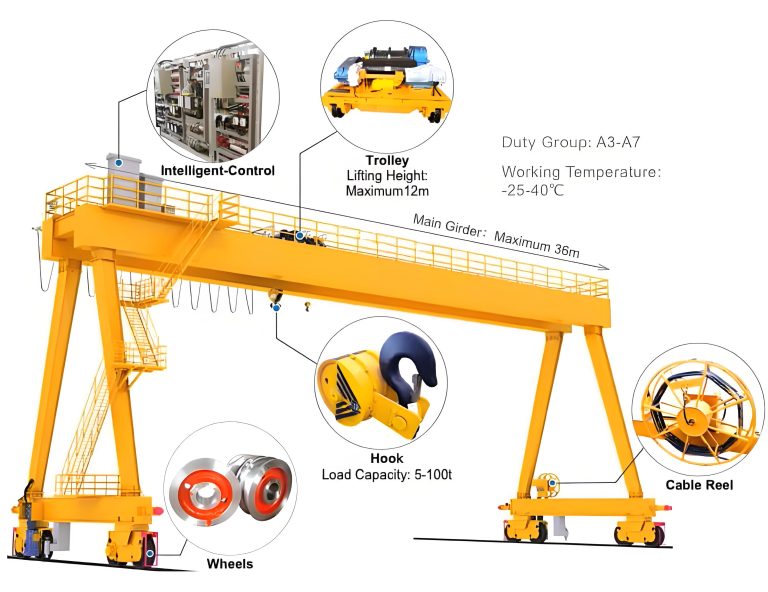

It has key components: main girders (top load-bearing structure), supporting legs (connecting girders to the ground), a traveling trolley (moves along girders), and a hoisting mechanism (lifts goods via hooks/spreaders). Unlike EOT cranes (running on overhead factory rails), its legs ride on ground rails, letting it operate in open areas. It’s widely used in ports, freight yards, and heavy industry to handle containers, steel beams, or large machinery.

The common types of gantry cranes include single girder gantry crane & double girder gantry crane and semi gantry crane (one leg on rail, one on the ground for narrow spaces), container gantry crane. Its different design enables flexible, long-distance lifting, fitting outdoor large-scale material transport needs.

MH Single Girder Gantry Crane

A Type Double Girder Gantry Crane

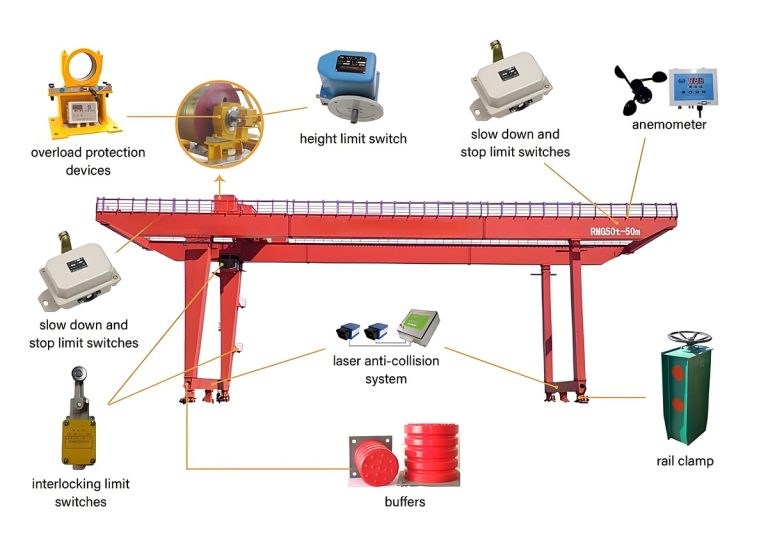

The gantry crane consists of main beam, raveling trolley, supporting legs, the hoisting mechanism, gantry crane traveling mechanism, the power supply system, cab, safety devices and other crane spare parts. The functions of each indispensable part are as follows:

Gantry cranes can move or lift materials in construction sites, bridge construction sites, shipbuilding sites, hydropower plants and ore zones. Dafang Crane, a professional gantry crane manufacturer and supplier in China, offers different kinds of gantry cranes. Such as single girder gantry cranes, double girder gantry cranes, semi gantry cranes, truss gantry cranes etc.

If you want to better understand different types of gantry cranes and their application scenarios. The following article will help to choose the most suitable types of gantry cranes to enhance productivity.

MH Single Girder Gantry Crane

L Type Single Girder Gantry Crane

L Type Single Girder Gantry Crane

U Double Girder Gantry Crane

U Type Double Girder Gantry Crane

A Type Double Girder Gantry Crane

Rubber Tyre Yard Gantry Crane

Gantry Crane

BMH Single Girder Gantry Crane

BMG Double GIrder Semi Gantry Crane

BMH Single Girder Semi Gantry Crane

BMG Double Girder Semi Gantry Crane

MH Truss Single Girder Gantry Crane

MG Truss Double Girder Gantry Crane

MH Single Girder Truss Gantry Crane

MG Double Girder Truss Gantry Crane

A gantry crane is suitable for open-area heavy-load lifting and transport across multiple sectors:

Construction Sites

Precast Plants

Warehouses

Manufacturing Workshops

Precast Industry

| Main Mode | L/MH/BMH |

|---|---|

| Lifting Capacity | 1-32 ton |

| Span | 3-31.5 m |

| Lifting Height | 6-24 m |

| Lifting Speed | 8,0.8/8 m/min, 7,0.7/7 m/min |

| Working temperature | -25℃~+40℃ |

| Power Supply | 3 Phase AC 380V 50HZ |

| Control mode | Remote Control/Pendent control/Cabin Control(customized) |

| Work Duty | A3-A5 |

| Main Mode | A/U/BMG |

|---|---|

| Lifting Capacity | 5-800 ton |

| Span | 5-35 m |

| Lifting Height | 5-30 m |

| Lifting Speed | 2-8 m/min, 1-20 m/min |

| Working temperature | -25℃~+40℃ |

| Power Supply | 3 Phase AC 380V 50HZ |

| Control mode | Remote Control/Pendent control/Cabin Control(customized) |

| Work Duty | A3-A7 |

Notice: The items listed only for reference. Customizable solutions are available.

| Types | Lifting Capacity | Price(USD) |

| Single Beam Gantry Crane | 1-32 ton | $5000 ~ $60000, depending on specifications |

| Double Beam Yard Gantry Crane | 5-500 ton (Special-purpose modes up to 800 ton) | $35000 ~ $80000, depending on specifications |

| Semi Gantry Crane (Single/Double Beam) | 2-10 ton, 5-320 ton | $12000 ~ $500000, depending on specifications |

| Truss Gantry Crane (Single/Double Beam) | 3-20 ton, 60-300 ton | $8000 ~ $600000, depending on specifications |

Now, you must have a comprehensive understanding of what is a gantry crane and you must know how to choose the most suitable types of gantry cranes to improve your working efficiency.

If you have interests in eot cranes, freestanding cranes, yard cranes, jib cranes, port cranes or crane parts, just directly contact our technicians and business manager. Later we will offer you the most professional guidance and support.