Get in Touch

Stella

News

In August 2025, Dafang received an email inquiry from a customer in Cyprus seeking a 10 Ton electric hoist. Cyprus serves as a vital hub for maritime transport, warehousing and cross-border logistics within the region. The client from a local logistics enterprise planned to introduce a 10 Ton electric hoist to support vertical lifting of building materials and industrial components. Thereby, it can substantially enhance warehouse turnover efficiency.

The project imposed stringent requirements on equipment safety, weather resistance, and EU compliance. The company searched globally for a reliable supplier with CE certification and rich export experience of electric hoist projects.

Following discussions, the company ultimately finalized the cooperation with Dafang Heavy Machinery Co., Ltd. (Dafang Crane). We recommanded and tailored a 10 Ton electric chain hoist with CE certificate. By adopting the hoist, the user can optimize lifting speed through a PLC intelligent control system and increase the single-shift workload by 30%.

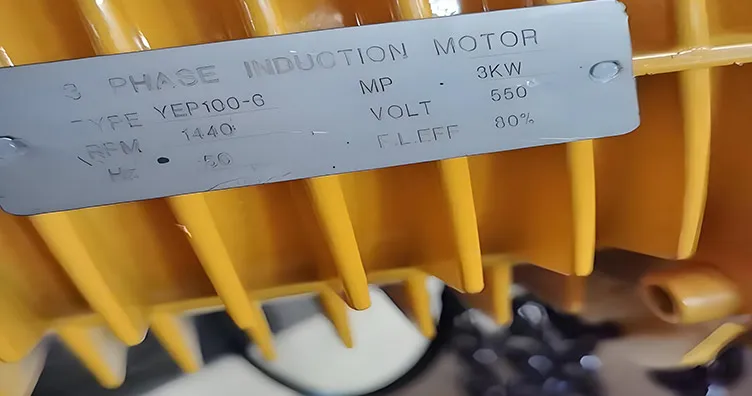

After communicating with the customer, our technical team, according to the customer’s needs, proposed a customized 10-ton electric hoist solution:

We developed a customized delivery solution to address the unique requirements of Cyprus shipping:

We used reinforced solid wood boxes that meet international shipping standards (the custom wooden boxes printed with "Dafang Crane" in the example image).

We also filled the boxes with shock-absorbing foam and moisture-proofing agents to prevent damage from moisture and bumps during long-distance transportation.

We prepared documents such as CE certification, certificate of origin, and Multilingual operation and maintenance manuals in advance.

With these advance preparations, we helped the customer quickly complete customs clearance.

Upon arrival at port of Limassol, our technical team provided on-site installation and commissioning guidance via remote video.

In addition, we also conducted online operation and maintenance training, focusing on regular chain lubrication and motor heat dissipation maintenance.

On September 13th, Dafang factory completed the manufacturing and rigorous quality checks to ensure the quality. On September 26th, the product was successfully shipped to Cyprus.

Three weeks later, the customer expressed their satisfaction after several uses of the hoist. And they praised the 10 Ton electric chain hoist’s efficiency and durability. Their warehouse and logistics handling efficiency increased by 35% and manpower costs were reduced by 40%. They spoke highly of Dafang team’s professional responsiveness and efficient execution. "Hope we can make further cooperation in the futuer." Later the manager added.

Henan Dafang Heavy Machinery Co., Ltd. is the TOP 10 crane manufacturer and supplier in China. We always provide high-quality products and the most suitable designs. We will focus on developing innovative cranes and other lifting equipment in the future.

Dafang Crane looks forward to more cooperation with global clients in the future. If you have any requirements for gantry cranes, bridge cranes, jib cranes, electric hoists etc., please contact us at any time!