Contattateci

Stella

Notizie

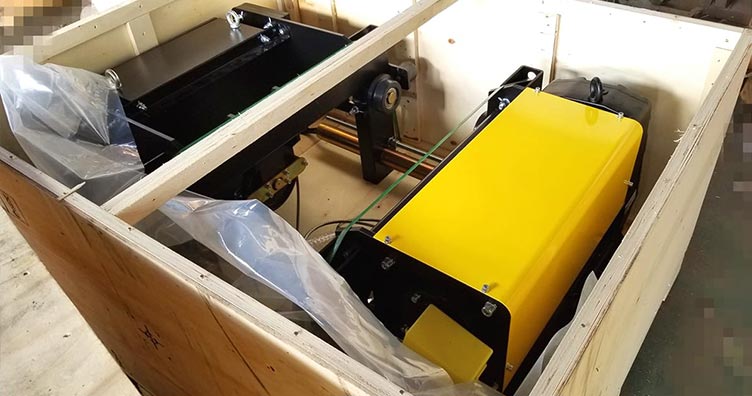

Last month, a Russian heavy machinery factory purchased 3 units of 5-ton European electric hoists and 2 units of 10-ton European electric hoists from Dafang Crane. All hoists are equipped with remote operation functions and meet FEM standards. The customer uses these hoists for precise lifting in their workshop. They required high safety, easy operation, and stable performance in dusty environments and extremely cold conditions.

Our team recommended European electric hoists with modular design and strong anti-interference capabilities based on the factory's actual needs. These customized hoists have passed the Russian GOST certification and been delivered successfully.

Lifting Capacity: 3 units of 5 tons, 2 units of 10 tons

Lifting Height: 12 meters

Control Method: Industrial wireless remote control

Power Supply: 220V/380V 50HZ

Motor Standard: FEM-certified motor

Lifting speed:

10-ton model: 0.7 m/min (low speed) / 7 m/min (high speed)

5-ton model: 0.8 m/min (low speed) / 8 m/min (high speed)

1. Anti-Interference Control: Uses 433MHz frequency hopping technology to allow interference-free operation of multiple devices.

2. Dual Braking System: Combines electromagnetic and mechanical brakes to ensure safer load suspension.

3. Environmental Adaptability: Equipped with -40°C cold-resistant cables and IP54 dustproof and waterproof rating, suitable for extreme cold and dusty environments.

4. Modular Flexible Design: Adopts FEM-standard modular structure, fitting different industrial scenarios with easy maintenance.

European electric hoist Suitable for workshop assembly line lifting, equipment maintenance, and short-distance cross-area handling across various industrial scenarios.

The technical director of the factory spoke highly of Dafang’s European electric hoist. He mentioned that the equipment has consistently operated stably in the harsh -40°C extreme cold and high-dust environment of the Siberian industrial zone, with precise and convenient wireless remote control. From demand communication to delivery, it only took 40 days, and the team’s professional responsiveness and efficient execution were highly trustworthy. Currently, the factory plans to purchase an additional 5 units in the second phase project and actively recommend the product to industry partners.

This cooperation marks an important breakthrough for Dafang in the global application of European-standard lifting equipment. We offer a rich product and multi-standard certification services, including gantry cranes, bridge cranes, as well as European electric hoists, ordinary wire rope electric hoists, metallurgical electric hoists, and explosion-proof electric hoists. These products are suitable for assembly lines, daily material handling, high-load metallurgical environments, and chemical explosion-proof scenarios, all of which can be matched with bridge cranes to improve efficiency. In the future, Dafang will continue to focus on complex working conditions worldwide, providing industrial customers with safer and more practical material handling solutions to boost manufacturing efficiency.