Productos

Lifting Capacity 1~250

Span(m) 5~31.5

Max Lifting Height(m) 6~28

Work Duty A4~A7

Overhead grab crane is a lifting equipment with special grabs, widely used in mining, metallurgy, cement, chemical industry and power plants. Conventional bridge cranes are inconvenient when lifting loose cargo. Therefore, the overhead grab crane with grab bucket is very important. It includes a remote grab bucket and a mechanical grab bucket, and has a working class of heavy-duty A6.

Dafang Crane is an outstanding overhead grab crane manufacturer and supplier in China. Overhead grab cranes are vital for bulk material handling in metallurgy, ports, and factories, using mechanical grabs to efficiently load or unload ores, coal and grains. They have two main designs: single girder overhead grab crane and double girder overhead grab crane. Each can tailor to customers' specific operational needs.

Single girder grab cranes, with 5-32 ton capacity and 7.5-15m spans, suit light-medium duties in workshops and warehouses. They are compact and cost-effective. Double girder grab cranes, handling up to 250 tons, excel in heavy-duty scenarios like mines and ports. They boast robust stability, custom designs and higher work duty of A5-A7 for demanding operations.

Show1

Show3

Show2

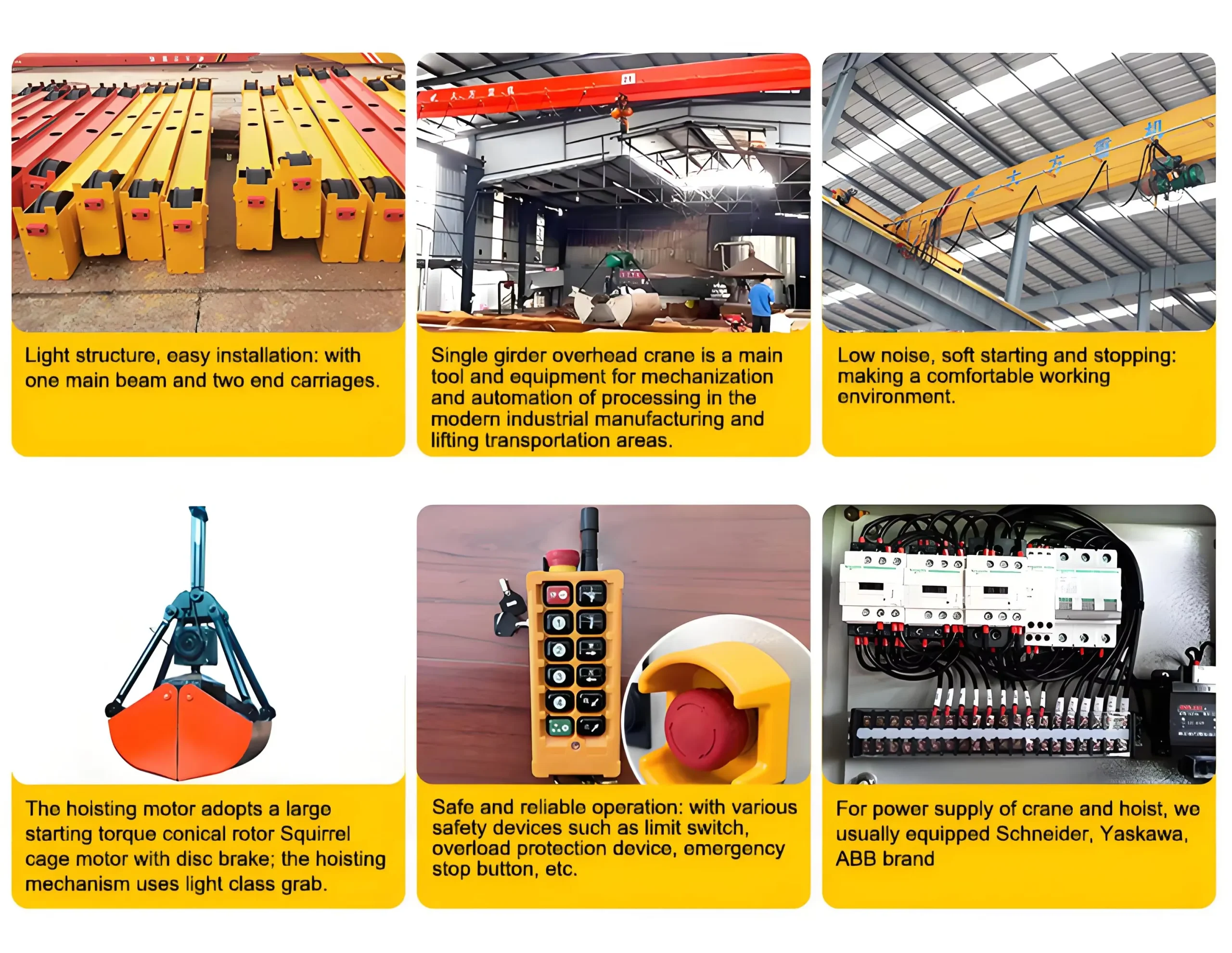

Single girder grab cranes are light-to-medium duty material handling equipment, featuring a single main load-bearing girder that ensures a compact structure and small floor space occupation. They typically handle 1–32 tons of loads with spans ranging from 7.5–15 meters.They are ideal for limited-space workplaces and for light-medium duties in workshops and warehouses.

Widely used in workshops, warehouses, and small-scale yards, they pair with single/double-rope grabs to handle grains, sand, small scrap steel, and other loose/bulk materials.

Simplified structure with a single beam, suited for light-medium duty, using electric hoists as the primary lifting mechanism. Equipped with electric hoists as lifting mechanisms and basic safety parts like limit switches, they offer low cost, easy maintenance, and meet moderate-frequency material transfer needs.

Double girder grab cranes are heavy-duty bulk material handling equipment, characterized by two parallel main girders that boost load-bearing capacity and operational stability.

Robust dual-beam design for heavy loads (up to 250 tons of loads with 10–40m spans, suiting high-intensity, heavy-duty scenarios. They boast robust stability, custom designs and higher work duty of A5-A7 for demanding operations.

Equipped with overload protection and anti-sway systems, they ensure safe, efficient transfer, meeting demanding industrial needs for large-volume, heavy-load material movement.

Widely used in mines, ports, and steel plants, they pair with mechanical/hydraulic grabs to handle ores, coal, steel slag, and other materials.

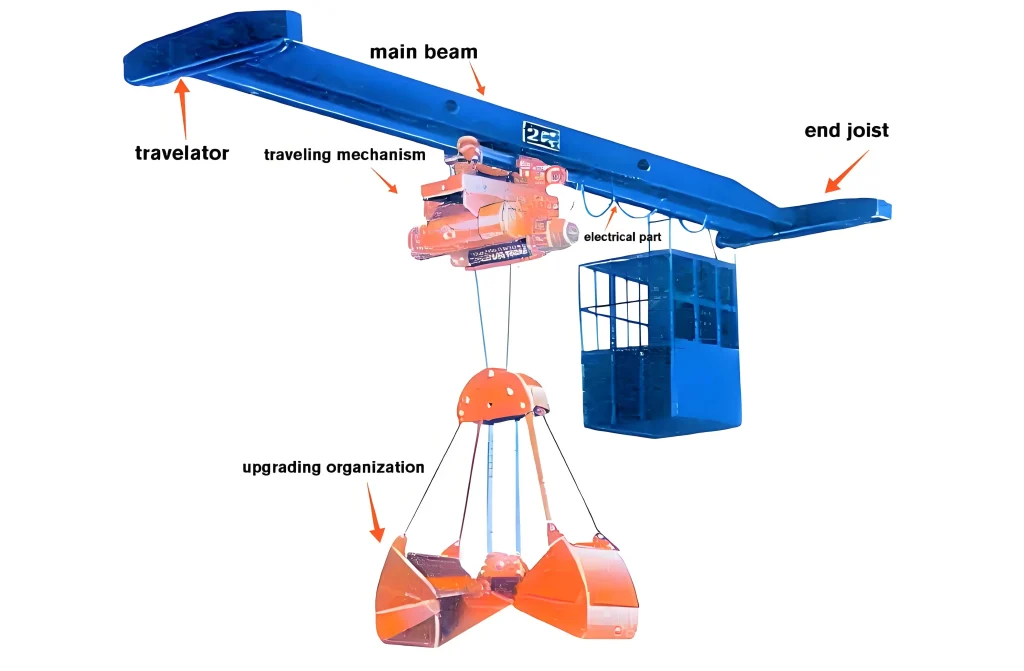

The overhead grab crane consists of box girder, end beam, trolley, grab bucket, wire rope, hoisting mechanism and other safety devices. The functions of each part are as follows:

For Material Handling

For Safety & Maintenance

Double Flap Grab

Multi Petal Grab Bucket

Four Cable Double Peel Grab

Hydraulic Grab

Mechanical Grab

PLC Control System

Overhead grab cranes are mainly used for material handling to efficiently accomplish the loading, unloading, handling, and stacking of goods.

Energy Recycling

Waste Recycling Plants

single-girder-overhead-grab-crane

Steel Mills

Bulk Materials Disposal

| Material Characteristics | Recommended Grab Type | Typical Applications |

|---|---|---|

| Large, hard materials (ore/rock) | Four-rope jaw hydraulic grab | Mines, heavy-duty ports |

| Loose, easily scattered materials (grain/coal powder) | 4-6 jaw mechanical grab | Grain depots, power plants |

| Powdery, easily dusty materials (cement/lime) | Sealed box grab (with dust cover) | Cement plants, chemical plants |

| Ferromagnetic materials (scrap steel/slag) | Electromagnetic jaw grab | Scrap steel recycling stations, steel mills |

| High-temperature/corrosive materials (slag/soda ash) | High-temperature resistant/stainless steel grab | Steel mills, salt plants, chemical plants |

Dafang supplies high quality overhead cranes, gantry cranes, jib cranes, electric hoists and crane spare parts etc. You can fill out the form below, and we will contact you as soon as possible

Stella