Ponte en contacto

Stella

Noticias

In industrial material handling, choosing the right crane is essential for operational efficiency, safety, and cost control. Whether you’re lifting containers at a port, moving heavy machinery in a factory, or transporting components in a warehouse, the decision between a gantry crane and a bridge crane can shape your workflow. Choosing rightly between a gantry crane and a bridge crane can im

prove your workflow and work efficiency. Their structural differences translate to distinct strengths in indoor vs. outdoor use, load capacity, and installation needs. Let’s dive into a detailed comparison to help you pick the perfect fit for your project.

| Performance Dimensions | Gantry Crane | Bridge Crane |

|---|---|---|

| Core Structure | Gantry frame and ground-mounted legs, without rails, flexible mobility | Suspended main beam, relying on factory wall or roof rail support |

| Environmental Adaptability | Primarily outdoor environments (construction sites, ports, shipyards, nuclear power plants) | Indoor use (factories, warehouses, production lines), requires matching factory load-bearing structure |

| Capacidad de elevación | 1-800 tons (800 tons for nuclear power plants) | 1-500 tons (500 tons for industrial applications) |

| Span Capacity | 4-145 meters (145 meters for shipyard models | Limited by factory span, typically 10-35 meters |

| Lifting Speed | 1-15 m/min, Stable opearation | 0.5-10 m/min, High-precision control |

| Installation Costs | Low costs (no building modification required) | High costs (requires factory reinforcement) |

| Installation Cycles | Short Cycles (can be moved within 60 minutes), complex models 1-2 weeks. | Long cycles (traditional methods 20 days, beam hoisting can be reduced to 1 week). |

| Maintenance features | Simple maintenance, no operating condition limitations | Need for regular maintenance, relying on factory operating space. |

| Mobility | Disassembled and relocatable, adaptable to multiple project scenarios. | Fixed in the factory building, can not be demolished and moved. |

| Application Scenarios | Logistics transfer, maintenance workshops, container lifting, ship assembly, bridge construction, nuclear power module lifting etc. | Machine tool handling, warehouse palletizing, steel plant equipment maintenance. |

Gantry cranes stand on their own two feet, so to speak. With a gantry-shaped frame and legs that ride on ground rails (or even no rails for light models), they don’t need a building to hold them up. That makes them perfect for outdoor jobs: think shipping yards lifting 100+ ton containers, open-air construction sites moving steel beams, or shipyards assembling large vessels. Their biggest perks? No need to modify existing structures, lower initial installation costs, and customizable spans (some stretch dozens of meters).

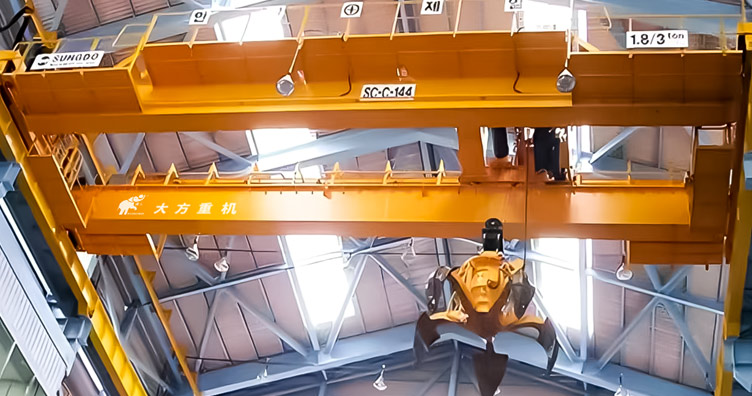

Bridge cranes, by contrast, are indoor specialists. They hang from the top of factories or warehouses, with their main beam spanning between crane rails mounted on the building’s walls. This “roof-supported” design means no legs get in the way—great for tight workshop spaces where you need unobstructed access to assembly lines or storage racks. They shine at precision tasks, like moving delicate machine parts in a manufacturing plant or loading pallets in a warehouse. But keep in mind: they depend on your building’s strength, so installation takes longer (you’ll need to add crane beams) and costs more upfront.

Flexibility and load capacity matter too. Gantry cranes can be disassembled and moved to new sites, while bridge cranes are stuck in one building. Both handle 1–500 tons, but gantry cranes edge out for ultra-heavy, long-span jobs, while bridge cranes excel at smaller loads that need pinpoint accuracy.

In short: Pick a gantry crane if you’re working outdoors, need big spans, or want lower setup costs. Go with a bridge crane if you’re inside a building and need precision. Either way, match the crane to your space, load, and workflow—and you’ll keep operations smooth.