Ponte en contacto

Stella

Noticias

To help you gain a clear understanding of 10 Ton overhead crane costs comparison and essential selection criteria, Dafang Crane writes this article according to the recent market data. We write the contents from three key aspects: price comparison, price-influencing factors, and the buying guidance to avoid common pitfalls.

When selecting 10 Ton bridge cranes, it is vital to balance initial costs against long-term value. Many buyers become fixated on price comparisons without understanding cost components or how to choose the appropriate model. Below, we will analyze cost components and offer practical guidance to avoid costly missteps.

10 Ton overhead crane costs vary significantly based on type and configuration. Below are 2025 market price ranges:

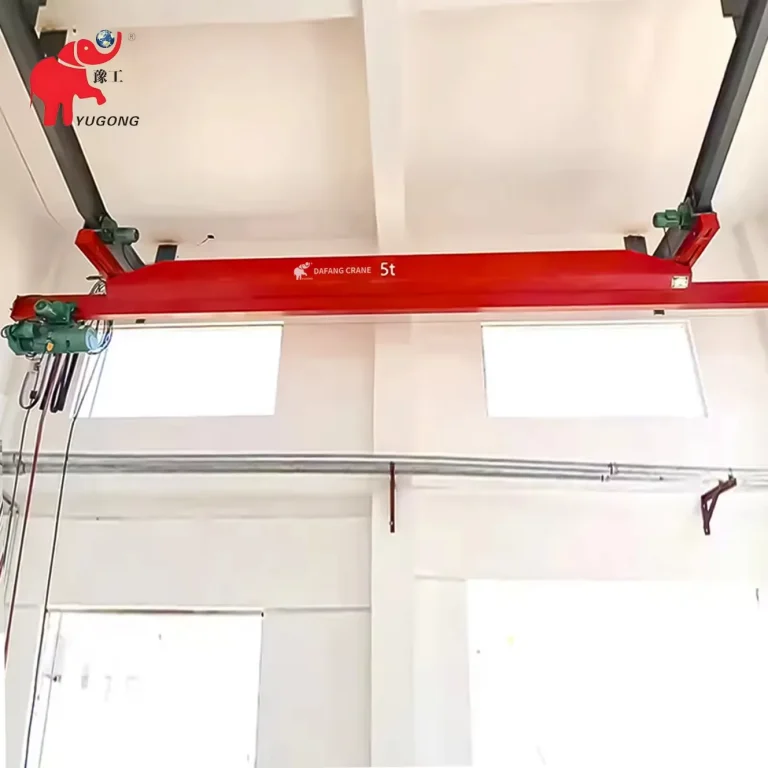

Workshops, Warehousing and logistics transfer depots, Light Assembly Line and Small Production Line

Heavy Machinery Factory, Large-Scale Equipment Workshop, High-temperature and Dusty Environments

Beyond the overhead cranes' buying prices, several additional expenses are also worth noting. Do not overlook the following additional 10 Ton overhead crane costs:

Installation Costs

Configuration Upgrades

Long-term maintenance

Dafang Crane is an internationally famous overhead bridge crane manufacturer and supplier. We have specialized in the crane industry for 20 years, exporting to over 200 countries. Therefore, you can have full confidence in the quality of our products and the assurance of our 24/7 services. We look forward to further cooperation with you.

In summary, when selecting a 10-tonne bridge crane, one must not focus only on the equipment's purchase price. It is also essential to comprehensively consider additional costs such as installation fees, configuration upgrade expenses, and long-term maintenance costs. Select the appropriate crane type and configuration based on actual operational requirements and budget.

If you want to learn about or buy other overhead cranes, gantry cranes jib cranes or container cranes, please read the following articles according to your preference.